Emissions from vehicles are a serious environmental issue. In an effort to reduce greenhouse gases and other harmful pollutants from cars automakers started introducing secondary air injection systems in the 90s.

Gas-powered vehicles burn fuel. This chemical reaction creates heat, water, and carbon dioxide. However, because the combustion is never fully complete, you also get byproducts. These byproducts include carbon monoxide, nitrogen oxides, and unburned hydrocarbons.

A secondary air injection system introduces fresh air into the exhaust system so that a second combustion can take place. The purpose of this second combustion is to burn any hydrocarbons that are left and to reduce carbon monoxide emissions.

Secondary air injection systems play an important part in reducing fog caused by unburned hydrocarbons and in reducing greenhouse gas emissions.

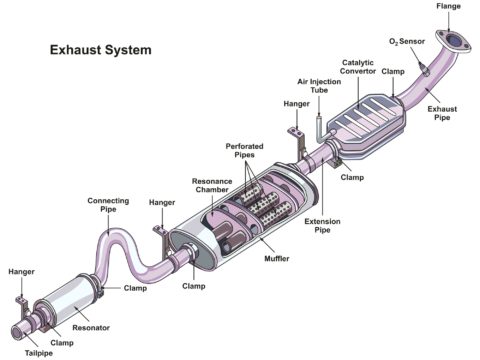

You can find some components of the secondary air injection system under the hood of your vehicle, including the air pump or smog pump and the air injection check valve. You’ll find other components underneath your vehicle with the exhaust system.

Contents

Five Causes of Secondary Air Injection Malfunction

The secondary air injection system can fail for different reasons.

1. Faulty Air Pump

A faulty pump is one of the most common causes of failure. It sometimes goes hand in hand with a bad valve that is letting moisture in and causing the valve and pump to corrode. However, electrical issues like a bad fuse can also cause the fog pump to fail.

If an air pump is going bad, you’ll often get a P0410 error code or a Check Engine light. You might notice some issues with idling or rough acceleration. In some cases, you might be able to hear the pump motor rattling.

2. Faulty Control Valve

A corroded seal can often cause the control valve to leak. The symptoms are usually similar to a faulty pump. If the control valve is stuck open, you will likely notice rough idling and accelerating.

3. Damaged lines

The lines and hoses can become blocked or cracked. You might see signs of wear-and-tear when inspecting these lines. They can also cause issues with the valves and lead to stalling.

4. Faulty Sensor

A faulty sensor will fail to activate when the exhaust system needs air. The other components of the system might be perfectly fine, but you will fail an emission test.

5. Faulty Control Circuit

The control solenoid and other relays can develop electrical issues. Besides failing an emission test, you might notice symptoms like stalling, rough acceleration, or error codes for the secondary air injection or exhaust system.

How to Test a Secondary Air Injection System

There are a few things you can do to test your secondary air injection system:

- Perform a visual inspection of the lines and hoses to see if there are any cracks or sharp turns that limit airflow.

- Locate the control valve and detect the hose from it. Inspect the sides of the valve to look for deposits. A dirty valve often indicates that airflow is insufficient.

- Find the air pump under the hood and inspect the fuses.

- With the engine cold, open the hood of your vehicle and start the engine. You should hear the air pump come on. You should also hear the pump go off when you turn the engine off. Listen for any unusual rattling or whirring noises coming from the pump.

- Use your car’s onboard diagnostic system to see if any codes related to the secondary air injection system pop up.

How Secondary Air Injection Works

Secondary air injection systems use different valves and sensors to detect when the exhaust system needs fresh air. The fog pump and air injection check valve play an important part since these components inject fresh air into the exhaust lines.

Parts of a Secondary Air Injection System

The parts of a secondary air injection system can vary from one vehicle to another. Here are the most common components you’ll find:

- The engine control unit manages the entire system. It uses a control relay to turn the air pump on and off as needed.

- There is a control valve or injection check valve that opens and closes to control how much fresh air reaches the air pump.

- The air pump or fog pump is one of the most important components. It captures fresh air and injects it into the exhaust system to allow for a second combustion.

- Some vehicles have a combination valve that prevents air from going out of the secondary air injection system. It’s a component you’ll usually find in older vehicles.

- Newer vehicles use a vacuum system or a control solenoid to manage the airflow instead of a combination valve.

- You’ll also find a sensor inside the exhaust system. This sensor or lambda control detects when the exhaust system needs more fresh air and sends a signal to the control unit.

- There are also various hoses and lines that connect these different components and allow air to flow into the exhaust system.

How to Fix a Secondary Air Injection

There are a few repairs that you can do yourself with some simple tools.

If the pump went bad, one of the things you can easily do yourself is to check the fuses and replace them. You can also replace the control valve or at the very least clean it to improve airflow.

Replacing the fog pump is also something you can do yourself with a few simple tools, but it’s best to have some experience with DIY repairs. And if you don’t mind more extensive repairs, you can also replace damaged hoses and lines or patch small leaks for a temporary solution.

It’s best to take your car to a mechanic if you can’t pinpoint the cause of the issue or aren’t comfortable with replacing the air pump yourself. Professional repairs for a secondary air injection system typically range from $200 to $400.

A new air pump usually costs less than $100, but this price can vary depending on the car you drive. You can find aftermarket injection control valves in the same price range, but you’ll have to spend $200 to $300 for an OEM. Hoses and lines are inexpensive and rarely cost more than $30.

FAQs

Here are a few additional things to know about secondary air injection systems.

Is Secondary Injection Really Necessary?

Technically, your car can run without this system. However, you will probably run into issues with engine performance. Plus, it might be illegal to drive with a faulty secondary air injection system depending on your state’s regulation regarding emissions.

How to Bypass a Secondary Air Injection System?

You can install a bypass kit. Keep in mind that your car won’t meet emission requirements.

What Does Insufficient Flow in a Secondary Air Injection System Mean?

It means that the system isn’t letting enough air in. The pump might be faulty, or the check valve might not open properly. A leak in one of the lines can also restrict airflow.

How to Clean a Secondary Air Injection System?

Injecting compressed air into the system can clear minor clogs. For more serious issues, you’ll have to disconnect the hoses and clean the ports and valves.

Can a Secondary Air Pump Cause a Misfire?

Yes, a misfire is a common sign of a faulty secondary air system. If the pump isn’t working properly, there will be too much fuel and not enough oxygen in your vehicle, which often results in a misfire. However, other issues can cause misfires.