The world of hypercar production is as thrilling as the cars themselves. From cutting-edge technology to the finest craftsmanship, building these high-performance machines is full of hidden details that most people never see. In this article, we’ll take a closer look at 15 surprising secrets behind the creation of hypercars, giving you an inside view of how these incredible vehicles come to life. Get ready to discover what goes on behind the scenes of the fastest cars on the planet.

Contents

Hand-Built Precision

Hypercars are known for their unrivaled quality, and much of this comes from their hand-built nature. Each piece, from the engine to the interior, is meticulously assembled by expert craftsmen. This level of attention ensures that every hypercar is free from manufacturing flaws, allowing for precision in performance and design. The process takes much longer than mass production, but the result is a car that feels unique, tailored, and built to perfection, which is why these cars command such high prices.

Exotic Materials

To achieve the ideal balance of strength and lightness, hypercar manufacturers turn to materials like carbon fiber, titanium, and aerospace-grade aluminum. These materials are significantly lighter than steel while offering immense strength and durability, critical for achieving the speeds and agility expected of hypercars. Carbon fiber is especially prized for its combination of lightness and rigidity, forming the body and chassis of many top models, helping them stay light yet incredibly strong.

Wind Tunnel Testing

Aerodynamics play a crucial role in a hypercar’s performance, and wind tunnel testing is key to refining a car’s shape for minimal drag and maximum downforce. Every contour, vent, and spoiler on a hypercar is shaped by hours in the wind tunnel. The results are cars that not only look sleek but are built to slice through the air at incredible speeds, reducing turbulence while increasing stability.

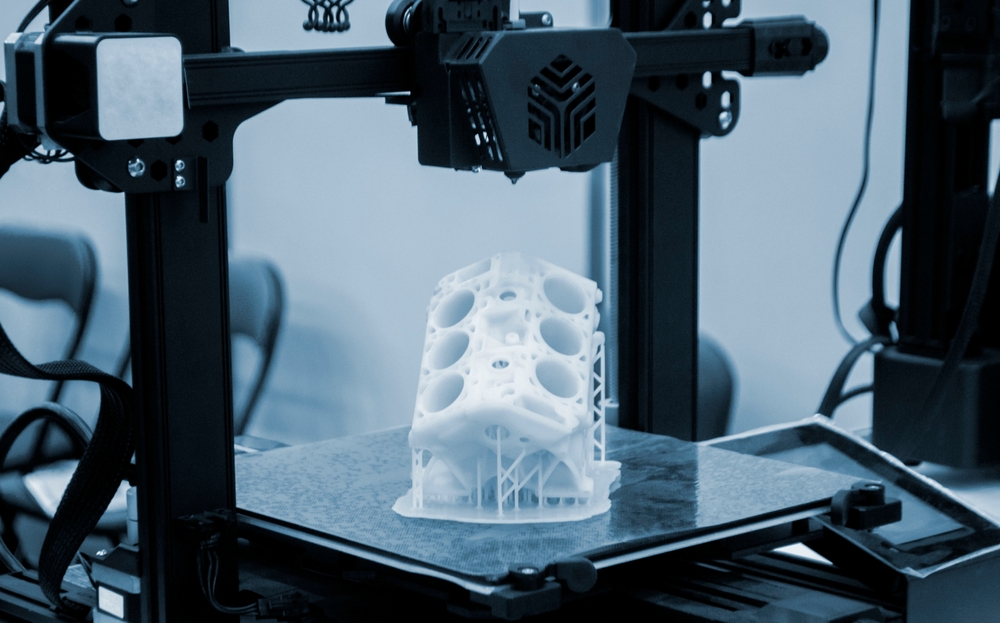

3D-Printed Parts

To create highly intricate or lightweight components, many hypercar manufacturers have adopted 3D printing technology. This allows for the creation of complex shapes that are either impossible or prohibitively expensive to make using traditional methods. From custom air intakes to finely tuned suspension components, 3D printing offers an unprecedented level of design freedom and precision, enhancing performance and reducing weight.

Active Aerodynamics

Many hypercars feature advanced active aerodynamics, which adjust in real-time to enhance performance. Wings, flaps, and splitters change position automatically depending on speed and driving conditions, helping the car maintain optimal downforce and traction at high speeds. These systems enable hypercars to balance top speed with stability and cornering ability, making them more versatile and safer even at extreme speeds.

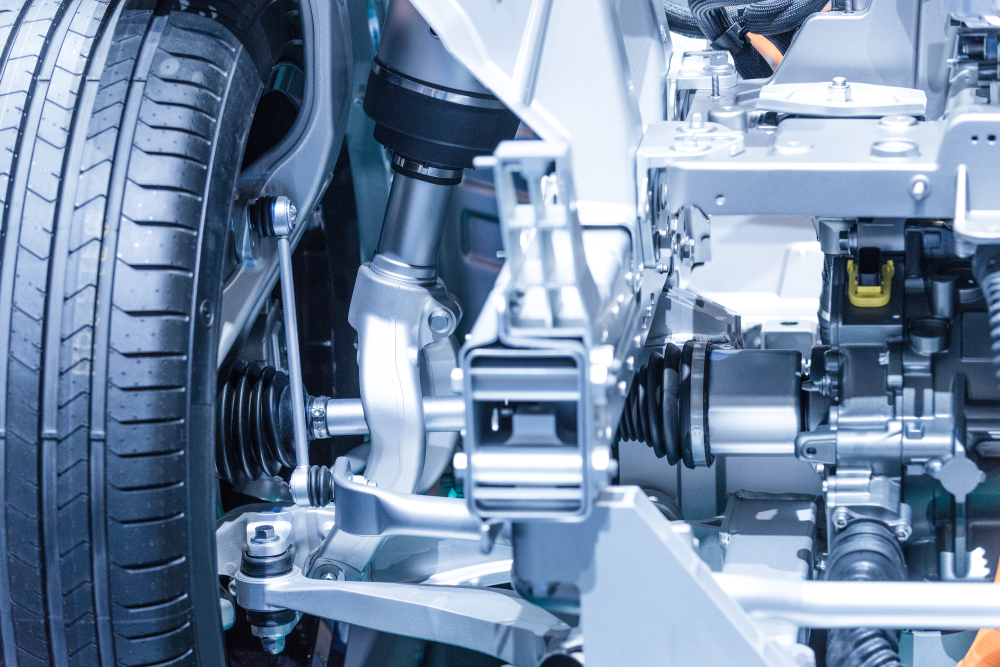

Hybrid Powertrains

Several hypercars utilize hybrid powertrains, blending internal combustion engines with electric motors to boost power and efficiency. Electric motors provide instant torque, which complements the high-end power of gas engines. This combination allows for blistering acceleration while also offering some level of fuel efficiency, particularly in city driving. The mix of old and new technology showcases the innovation within hypercar design.

Limited Production Runs

Exclusivity is a key factor in the allure of hypercars, with many models limited to fewer than 100 units. This rarity increases their desirability, making them not just high-performance vehicles but coveted collectibles. Limited production also allows manufacturers to maintain a high standard of quality, giving each car the attention it deserves while driving up market value.

Secret Testing Locations

Before a hypercar hits the market, it undergoes rigorous testing in secret locations. These include private airstrips, closed highways, and remote desert roads, allowing engineers to push the cars to their limits without interference. This testing ensures that hypercars are capable of handling the speeds and conditions promised by their specifications, ensuring top performance when they reach buyers.

Advanced Driver Aids

Despite their extreme performance, hypercars are equipped with sophisticated driver aids to help control their immense power. These systems include traction control, stability management, and adaptive suspension, all designed to make the car more controllable, even at extreme speeds. Without these aids, driving a hypercar would be dangerous for all but the most experienced drivers.

Extensive R&D Costs

The research and development behind a hypercar can cost hundreds of millions of dollars. From aerodynamic refinement to materials testing, each component of a hypercar requires extensive testing and development. The costs are a reflection of the advanced technology and engineering expertise involved, which helps push the boundaries of what a car can do.

Customization Options

Hypercar buyers often have the opportunity to fully customize their vehicles. This includes selecting bespoke interior materials, colors, and even performance tweaks. Each car can be as unique as the buyer, creating a driving experience tailored precisely to their preferences. Customization allows for a truly personal touch, making each hypercar not only rare but unique.

Specialized Tires

The tires for hypercars are engineered specifically for their needs, capable of handling incredible speeds and forces. They are built from high-performance materials that provide maximum grip while maintaining durability under extreme stress. These tires can resist the heat generated by high-speed driving and offer superior handling during aggressive cornering, making them essential for the safety and performance of the vehicle.

Extreme Durability Testing

Hypercars are subjected to grueling durability tests to ensure they can perform at high levels for extended periods. These tests include running the car at top speed for hours and simulating long-term wear. This testing ensures that the car’s components, from the engine to the body, can handle the rigors of high-speed driving, proving that these machines are not just fast but durable.

Pre-Orders Before Production

Most hypercars are sold out before production begins, thanks to an eager base of collectors. These pre-orders often happen before the final specifications are even released, with buyers confident in the brand’s reputation. This creates an aura of exclusivity, as only a few privileged individuals will own one, further driving up demand and value.

Intensive Quality Control

Each hypercar undergoes a rigorous quality control process, often involving hundreds of checks before leaving the factory. This attention to detail ensures that every component is perfectly aligned, functional, and visually flawless. The meticulous process ensures that each car meets the incredibly high standards expected of these elite machines.

This article originally appeared in MyCarMakesNoise.

More from MyCarMakesNoise

25 Iconic Race Cars That Redefined Speed and Style

Race cars are not just about speed and performance; they’re also about making a visual statement. From bold colors to sleek lines, some race cars stand out not only for their engineering but also for their striking looks. In this article, we’ll take a look at the 25 most eye-catching race cars in history that have turned heads both on and off the track. Read More

20 Functional Utility Vehicles That Put Practicality Over Style

Utility vehicles are designed for practicality and performance, but not all hit the mark when it comes to style. Some models, despite their functionality, have failed to impress with their design. Read More

20 Cars That Struggled with Aerodynamics and Performance

Aerodynamics play a crucial role in a vehicle’s efficiency and performance. However, some automobiles have designs that hinder their aerodynamic capabilities, resulting in poor fuel economy and handling. Here are some automobiles with the worst aerodynamic designs, highlighting the challenges they face on the road. Read More