Engines are the heart of every automobile, driving innovation and transforming the way we travel. Over the years, groundbreaking engine technologies have revolutionized the automotive industry, enhancing performance, efficiency, and sustainability. In this article, we explore 20 game-changing engine innovations that have left a lasting impact on the world of cars.

Contents

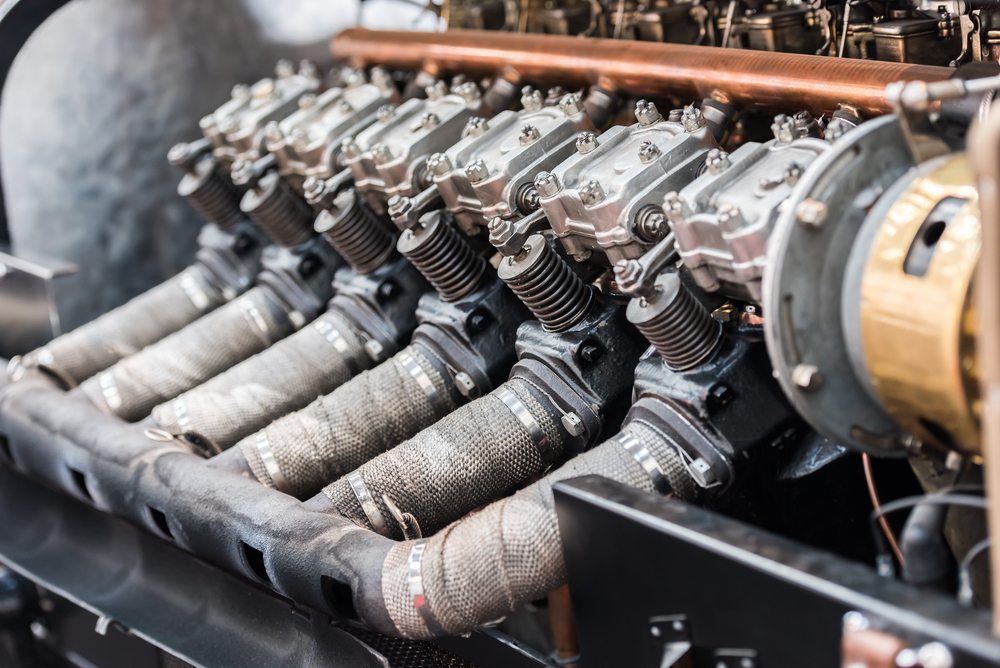

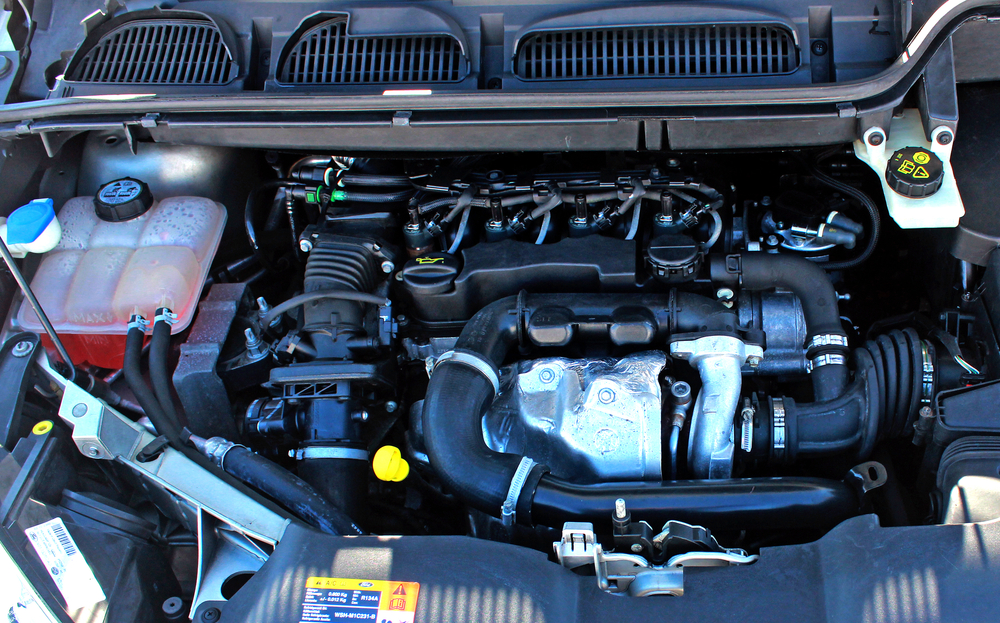

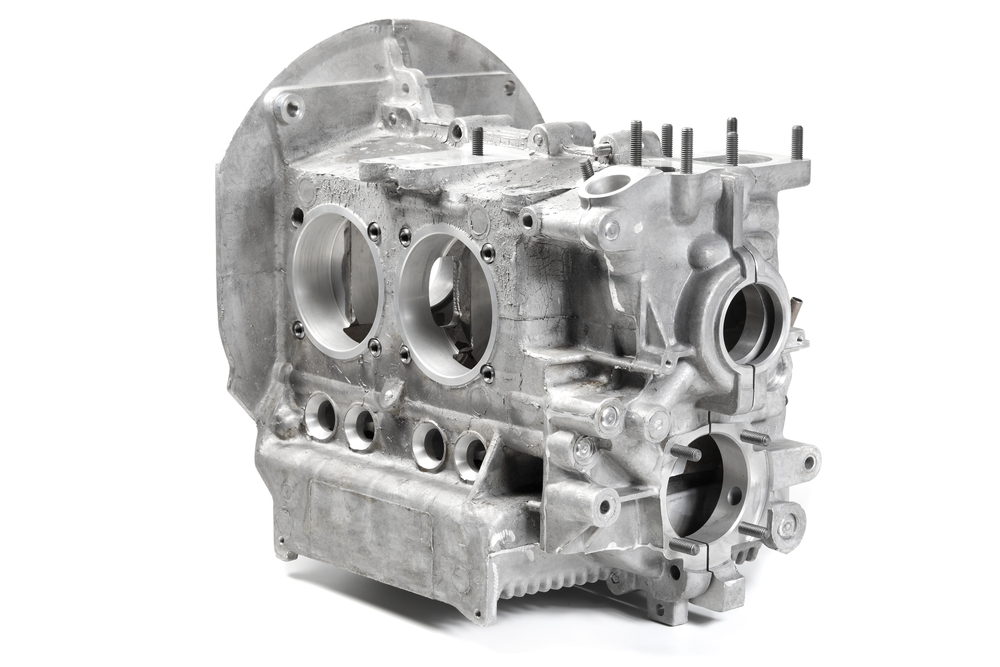

Internal Combustion Engine

The internal combustion engine (ICE) is the cornerstone of modern automotive engineering. It converts fuel into mechanical work through a controlled explosion of fuel and air within cylinders. This innovation paved the way for the mass production of automobiles, offering unmatched power, reliability, and versatility compared to earlier steam engines.

Turbocharging

Turbocharging revolutionized engine performance by forcing more air into the combustion chamber, allowing for more fuel to be burned and significantly increasing power output. This technology, first popularized in high-performance and race cars, is now common in many passenger vehicles due to its ability to enhance engine efficiency and power without significantly increasing engine size.

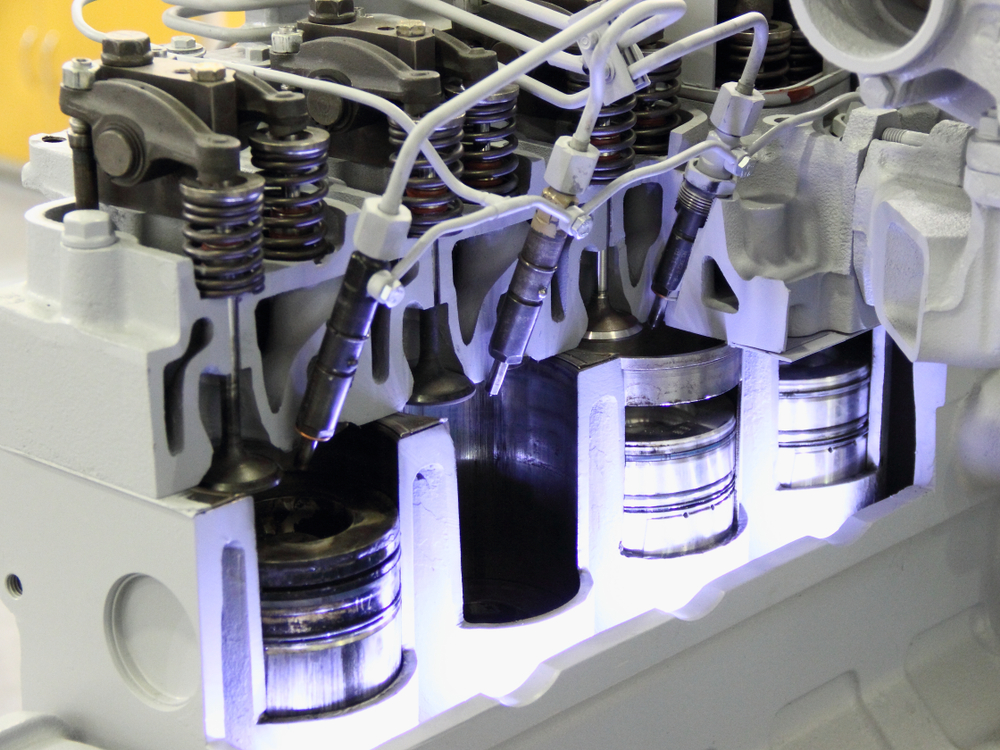

Fuel Injection

Fuel injection replaced carburetors by delivering fuel directly into the engine’s combustion chamber or intake manifold with precise control. This innovation improved fuel efficiency, reduced emissions, and enhanced engine performance. Electronic fuel injection systems, in particular, allowed for more accurate fuel delivery and better adaptation to changing driving conditions.

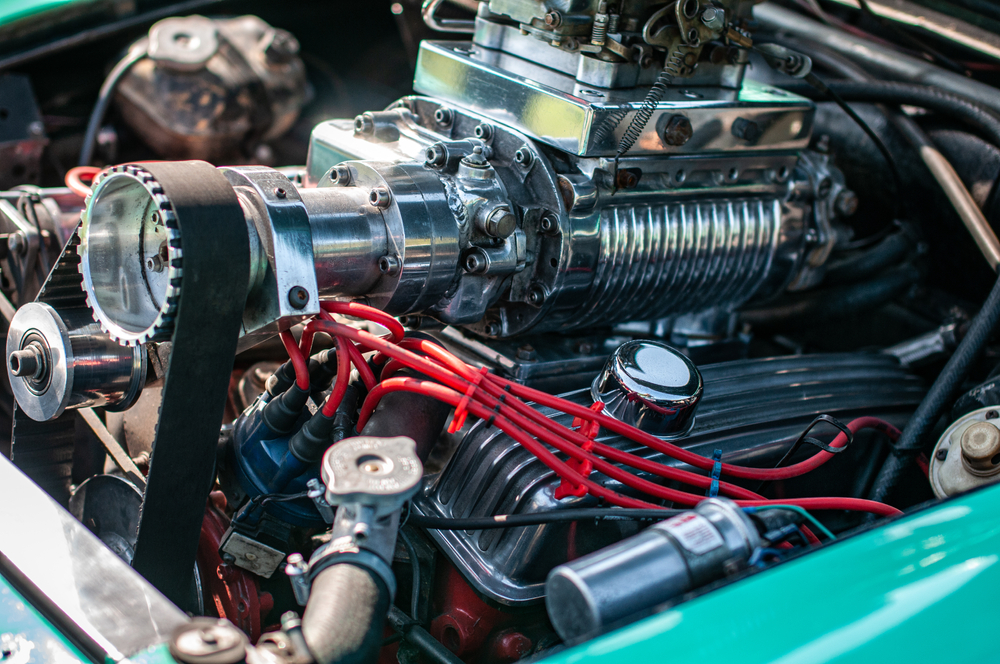

Supercharging

Superchargers, driven directly by the engine, compress the air entering the engine to increase its density and, consequently, its power output. Unlike turbochargers, superchargers provide immediate power boost without the lag, making them ideal for performance vehicles and applications requiring rapid throttle response.

Variable Valve Timing (VVT)

VVT systems adjust the timing of valve operation to optimize engine performance across a range of speeds and loads. By varying the opening and closing times of the intake and exhaust valves, VVT enhances power output, fuel efficiency, and emissions control, adapting the engine’s characteristics to driving demands.

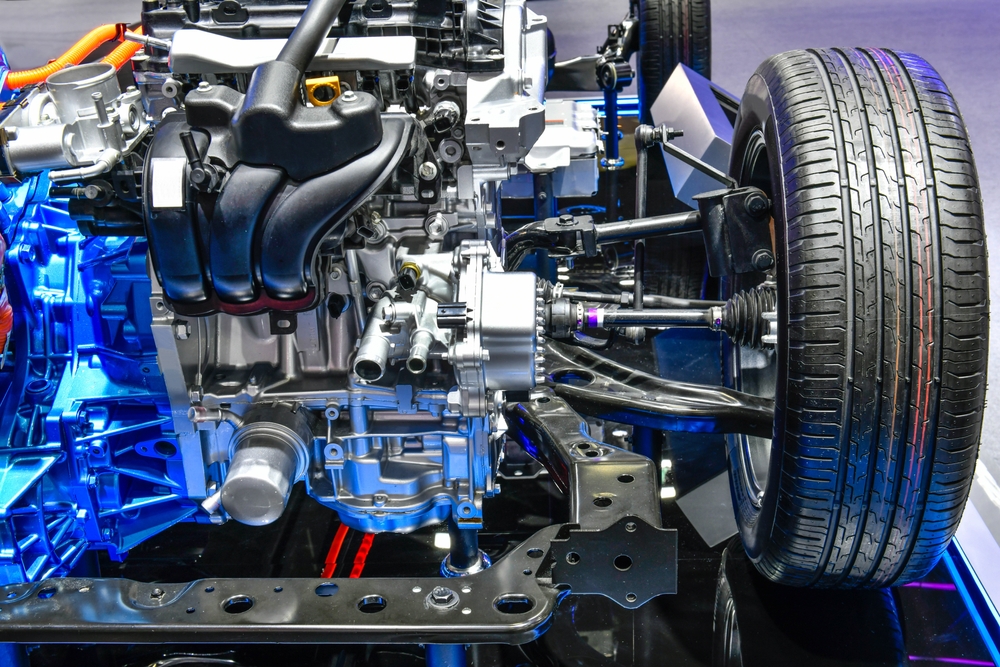

Hybrid Technology

Hybrid technology combines internal combustion engines with electric motors, offering a significant leap in fuel efficiency and reduced emissions. Hybrids use regenerative braking to recharge batteries, and their electric motors provide assistance during acceleration, improving overall efficiency and enabling short-distance zero-emission driving.

Electric Engines

Electric engines represent a major shift from traditional internal combustion engines, using electricity stored in batteries to power the vehicle. They offer zero emissions, high efficiency, and instant torque, making them an attractive alternative for sustainable transportation. Advances in battery technology continue to extend their range and reduce charging times.

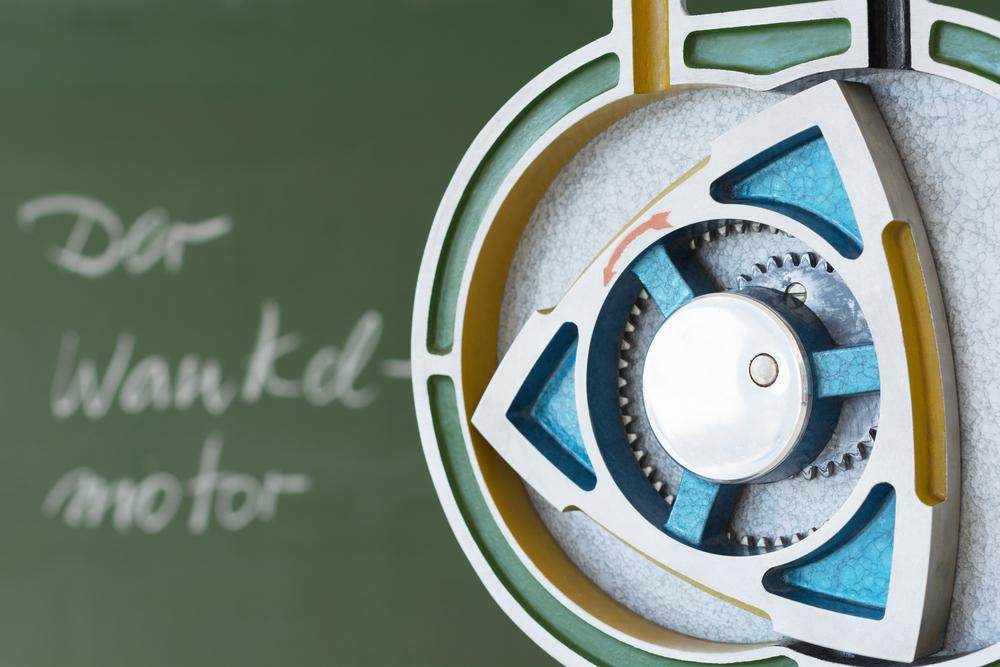

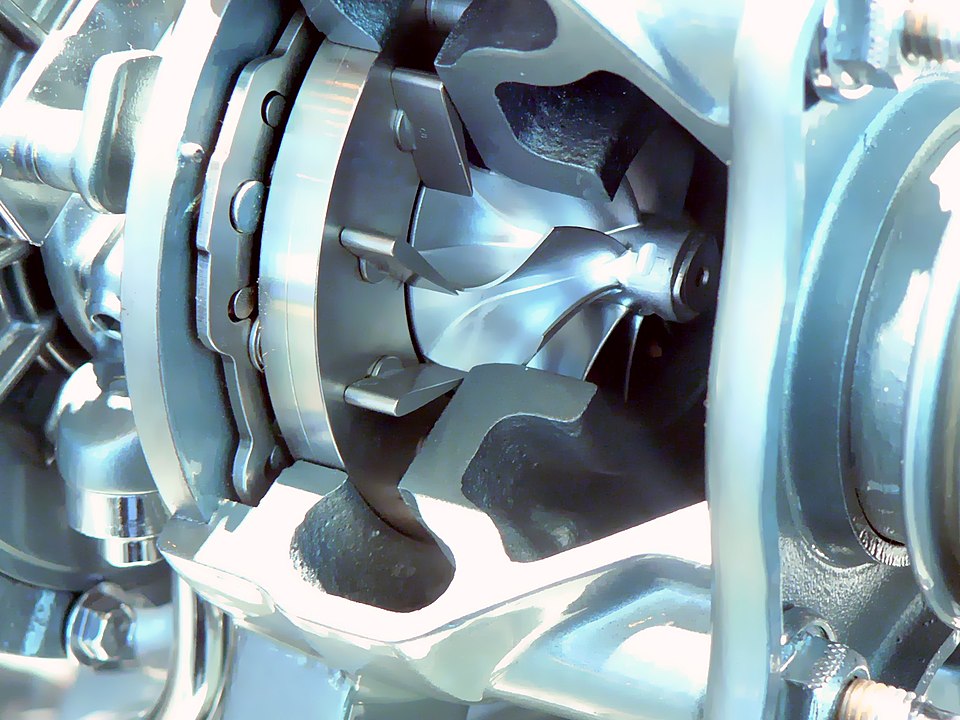

Rotary (Wankel) Engine

The rotary engine, invented by Felix Wankel, features a unique design with a triangular rotor spinning in an oval-shaped chamber. This compact engine has fewer moving parts, leading to a high power-to-weight ratio and smooth operation. Although less fuel-efficient than traditional piston engines, its lightweight and compact design has been used in performance-oriented vehicles like the Mazda RX series.

Hemispherical Combustion Chambers

Hemispherical combustion chambers, or “hemi” engines, feature a dome-shaped chamber that allows for larger valves and a more efficient air/fuel mixture burning. This design increases power output and fuel efficiency by improving the engine’s breathing capabilities and combustion efficiency.

Direct Fuel Injection

Direct fuel injection (DFI) systems deliver fuel directly into the combustion chamber rather than the intake manifold. This method allows for finer control over the fuel/air mixture, resulting in increased power, better fuel economy, and reduced emissions. DFI is particularly effective in turbocharged and high-performance engines.

Start-Stop Systems

Start-stop systems automatically shut off the engine when the vehicle comes to a stop and restart it when the driver presses the accelerator. This technology reduces fuel consumption and emissions, particularly in urban driving conditions with frequent stops and starts. It enhances overall efficiency without compromising performance.

Diesel Engines

Diesel engines use compression ignition rather than spark ignition, offering higher fuel efficiency and torque compared to gasoline engines. They are particularly valued in commercial and heavy-duty applications for their durability and fuel economy. Modern advancements have also reduced their emissions, making them more environmentally friendly.

Air-Cooled Engines

Air-cooled engines, used notably in older Volkswagen Beetles and Porsche 911s, eliminate the need for a liquid cooling system by using air to dissipate heat. This simplifies engine design, reduces weight, and lowers the risk of coolant leaks, making them reliable and easy to maintain, particularly in older and classic vehicles.

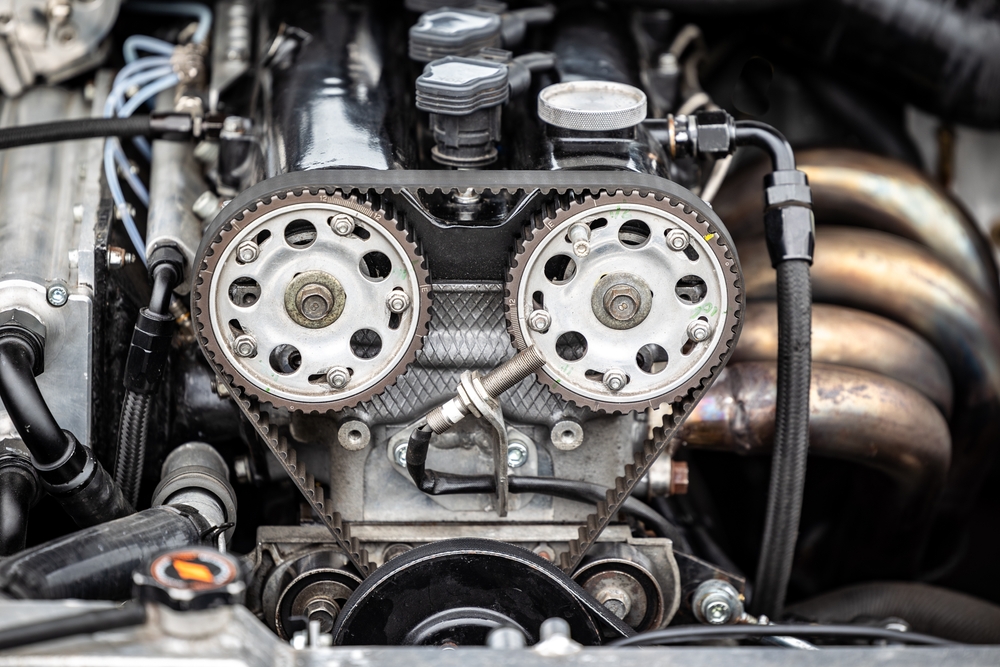

Overhead Camshafts (OHC)

Overhead camshaft engines position the camshaft(s) directly above the engine’s valves, improving timing precision and allowing for higher engine speeds. This configuration enhances performance and efficiency compared to traditional pushrod engines. OHC and dual overhead camshaft (DOHC) designs are common in modern high-performance and high-efficiency engines.

Twin-Cam (DOHC) Engines

Twin-cam or dual overhead camshaft (DOHC) engines feature two camshafts per cylinder bank, allowing for more precise control of valve timing and operation. This design improves airflow, increasing power and efficiency. DOHC engines are common in performance-oriented vehicles due to their ability to enhance high-revving capabilities.

Common Rail Diesel Injection

Common rail diesel injection systems use a single high-pressure fuel rail to deliver fuel to multiple injectors. This system provides more precise control over fuel delivery, resulting in cleaner combustion, improved fuel efficiency, and reduced emissions. It is a significant advancement in diesel engine technology.

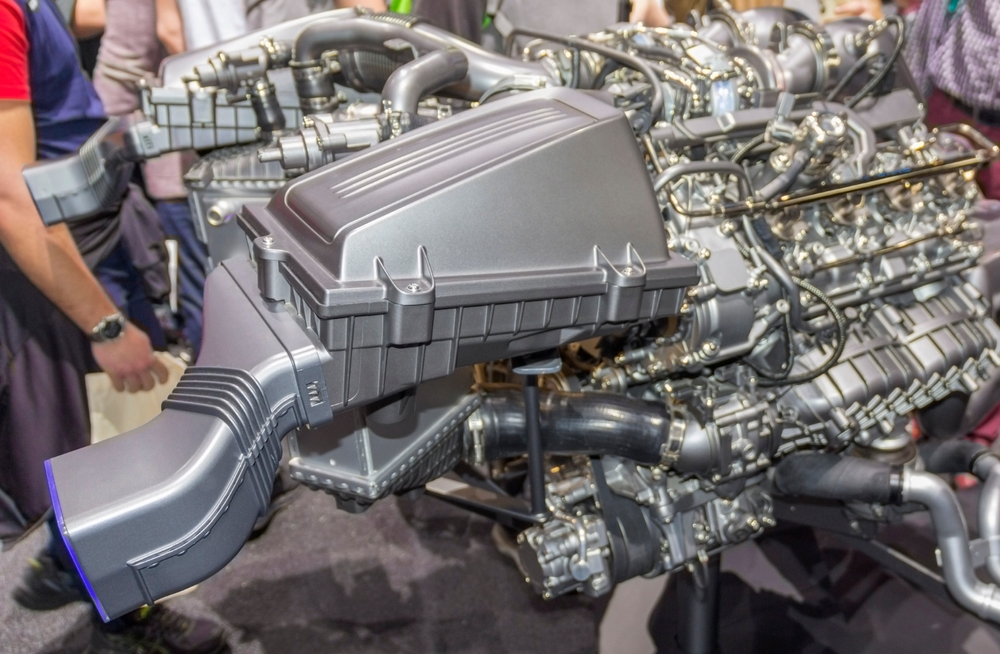

EcoBoost Engines

Ford’s EcoBoost engines combine turbocharging and direct fuel injection to deliver high power and torque with smaller, more efficient engines. These engines offer the performance of larger engines with the fuel economy of smaller ones, making them popular in a range of vehicles from performance cars to trucks.

Variable Geometry Turbochargers (VGT)

VGT technology adjusts the turbocharger’s vane geometry to optimize airflow across a wider range of engine speeds. This results in improved low-end torque and high-end power, enhancing overall engine performance and efficiency. VGTs are commonly used in both diesel and gasoline engines to reduce turbo lag and increase responsiveness.

Regenerative Braking

Regenerative braking systems recover energy typically lost as heat during braking and convert it into electrical energy to recharge hybrid or electric vehicle batteries. This technology improves overall energy efficiency and extends the driving range of electric and hybrid vehicles, making them more practical and sustainable.

Bi-Turbo Engines

Bi-turbo or twin-turbo engines use two turbochargers of different sizes to provide both low-end torque and high-end power. The smaller turbocharger operates at lower engine speeds for quick response, while the larger one kicks in at higher speeds for maximum power. This configuration offers a broader powerband and improved performance across the engine’s operating range.

This article originally appeared in MyCarMakesNoise.

More from MyCarMakesNoise

20 Car Features Drivers Are Begging Automakers to Remove

Not all car features are welcomed by drivers. Some can be more annoying than useful, adding complexity or distraction. Read More.

16 Potential Pitfalls of Owning a Luxury SUV

Owning a luxury SUV can be a thrilling experience, but it comes with its own set of challenges. From high maintenance costs to potential safety concerns, there are several factors to consider before making such an investment. Read More.

13 of the Rarest BMW Cars to Ever Hit the Road

BMW has long been celebrated for its luxury, performance, and innovative design blend. Over the years, the Bavarian automaker has crafted numerous models that not only pushed the boundaries of automotive engineering but also captured the imaginations of car enthusiasts worldwide. Read More.