Truck manufacturing has seen game-changing developments that have transformed the industry, making trucks more powerful, efficient, and versatile than ever before. From the integration of electric drivetrains and hybrid technology to advanced safety features like automatic braking and lane assist, these innovations are reshaping how trucks are built and driven. In this article, we’ll explore the key advancements in truck manufacturing that have revolutionized performance, sustainability, and driver experience, showing how these developments continue to push the boundaries of what trucks can do.

Contents

Turbocharged Diesel Engines

The introduction of turbocharged diesel engines in truck manufacturing was a game-changer, drastically improving both power and fuel efficiency. By forcing more air into the combustion chamber, turbochargers increase engine power without the need for a larger engine. This development allowed trucks to haul heavier loads while using less fuel. Turbocharging, which became mainstream in the late 1980s and 1990s, remains a critical advancement, particularly for heavy-duty trucks that require immense torque for towing and long-haul transport. Modern examples like Ford’s Power Stroke diesel engines demonstrate the continued importance of this innovation.

Automatic Transmissions in Heavy-Duty Trucks

The transition from manual to automatic transmissions in heavy-duty trucks revolutionized the trucking industry by making driving easier and more accessible to a wider range of drivers. With automatic transmissions, truck drivers no longer needed to master complex gear-shifting techniques, which reduced fatigue and allowed for more focus on road safety. It also improved fuel efficiency, as the transmission could optimize shifts better than many manual drivers. Companies like Allison Transmission pioneered this technology, and it became more widespread in the late 1990s and early 2000s.

Electronic Logging Devices (ELDs)

Electronic Logging Devices (ELDs) transformed truck manufacturing by ensuring compliance with hours-of-service (HOS) regulations. These devices automatically record a driver’s hours of operation, replacing the traditional paper logbooks. Introduced as a legal requirement in the U.S. in 2017, ELDs help reduce driver fatigue by ensuring rest periods are properly observed and improve overall road safety. They also provide real-time data to fleet managers, improving efficiency and reducing instances of regulatory violations. ELDs are now a standard in truck manufacturing, incorporated into the design of new models.

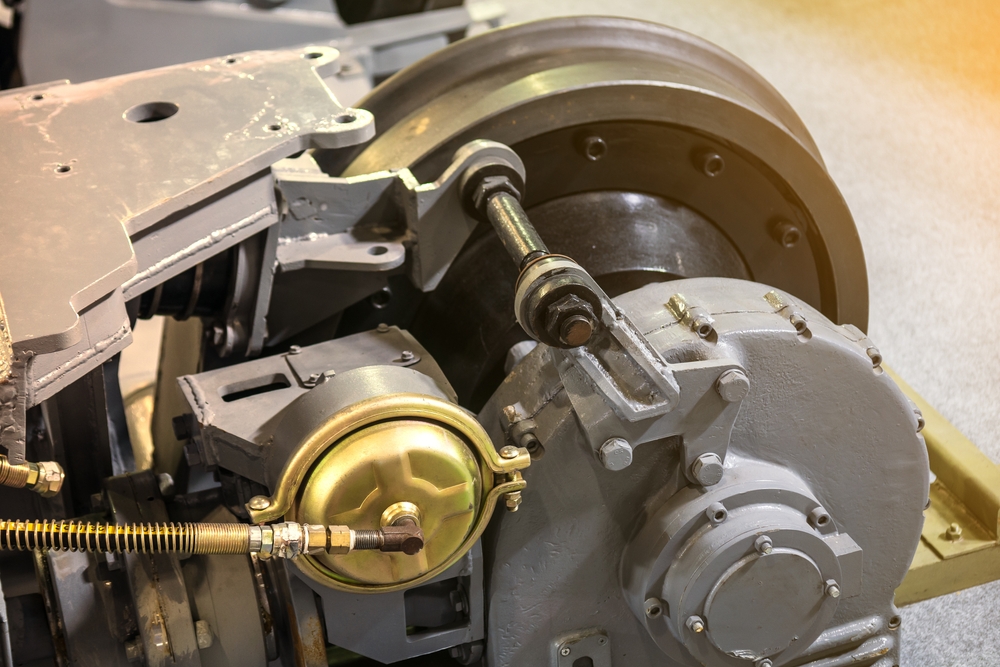

Air Disc Brakes

Air disc brakes have become a major advancement in truck manufacturing, improving braking performance, especially in heavy-duty trucks. Unlike traditional drum brakes, air disc brakes offer better heat dissipation, reduce brake fade, and provide shorter stopping distances. This development enhances safety, especially in trucks carrying heavy loads or driving in mountainous terrain. Many truck manufacturers began integrating air disc brakes in the early 2000s, and they are now commonly used in commercial vehicles worldwide, significantly reducing maintenance costs and improving safety.

Advanced Driver Assistance Systems (ADAS)

The integration of Advanced Driver Assistance Systems (ADAS) in trucks has been a game-changer for improving safety and reducing accidents. These systems, which include lane departure warnings, adaptive cruise control, automatic emergency braking, and blind-spot monitoring, help drivers maintain control in difficult situations. ADAS features were introduced in trucks in the late 2010s, with companies like Volvo and Daimler leading the way. They have since become standard in many modern trucks, enhancing both driver safety and overall road safety by reducing human error.

Regenerative Braking Systems

Regenerative braking systems, primarily introduced in hybrid and electric trucks, capture energy that would otherwise be lost during braking and convert it into usable power. This development is game-changing because it improves fuel efficiency and extends the range of hybrid and electric trucks. Companies like Tesla and Rivian have implemented this technology in their electric trucks, demonstrating its potential to reduce fuel consumption and emissions. Regenerative braking is a key innovation in the shift towards more sustainable and efficient transportation.

Lightweight Materials

The use of lightweight materials such as aluminum and high-strength steel in truck manufacturing has had a significant impact on fuel efficiency and performance. By reducing the overall weight of trucks without compromising strength, manufacturers have been able to increase fuel economy and payload capacity. Ford’s introduction of an aluminum-bodied F-150 in 2015 is a prime example of this innovation. The lighter weight allows for better fuel efficiency while maintaining the truck’s durability and towing capacity, setting a new standard in the industry.

Aerodynamic Design Enhancements

Improved aerodynamics in truck design has been a game-changer for fuel efficiency and overall performance. Manufacturers began focusing on reducing drag in the 1980s, but advancements have continued with features like rounded edges, streamlined mirrors, and roof fairings. These improvements reduce air resistance, allowing trucks to move more efficiently at highway speeds, which results in significant fuel savings. Modern trucks, such as the Tesla Semi, take aerodynamics even further, achieving sleek, futuristic designs that minimize drag and maximize range.

Fully Electric Trucks

The development of fully electric trucks represents a paradigm shift in the trucking industry, with companies like Tesla, Rivian, and Volvo leading the charge. Electric trucks offer zero emissions, reduced operating costs, and lower maintenance requirements compared to traditional diesel-powered vehicles. The Tesla Semi, unveiled in 2017, promises a range of up to 500 miles on a single charge, revolutionizing long-haul trucking by reducing the industry’s carbon footprint. As charging infrastructure improves, electric trucks are set to become a more viable and widespread option for both local and long-distance transport.

Hybrid Powertrains

Hybrid powertrains combine traditional internal combustion engines with electric motors, offering a middle ground between fully electric and gasoline/diesel-powered trucks. Hybrid trucks reduce fuel consumption and emissions, making them more environmentally friendly. Companies like Toyota and Volvo have developed hybrid trucks that significantly improve fuel efficiency, especially in urban environments with frequent stop-and-go traffic. This development is critical as the industry transitions toward greener alternatives while maintaining the power and range required for long-haul and commercial trucking.

Autonomous Trucking Technology

Autonomous trucking technology is transforming the trucking industry by promising greater efficiency, safety, and cost savings. Self-driving trucks, developed by companies like Waymo and TuSimple, use advanced sensors, cameras, and artificial intelligence to navigate roads without human intervention. This technology reduces driver fatigue and the risk of human error, potentially lowering accident rates. Though still in testing phases, autonomous trucks have the potential to revolutionize long-haul freight transport by allowing continuous operation, improving delivery times, and reducing labor costs.

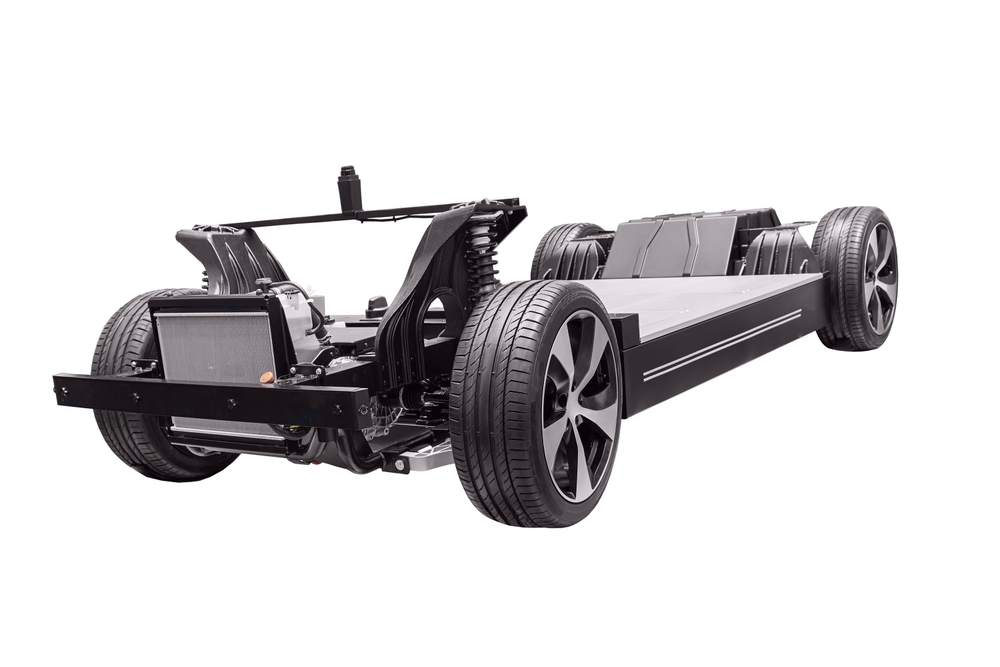

Modular Vehicle Platforms

Modular vehicle platforms are changing truck manufacturing by allowing manufacturers to produce multiple truck models using the same basic components. This approach reduces production costs and speeds up the development of new models. Companies like General Motors and Ford have embraced modular design, enabling them to offer a wide variety of trucks with different powertrains, body styles, and configurations while maintaining manufacturing efficiency. This flexibility also allows for easier upgrades and changes in technology, such as integrating electric or hybrid powertrains into existing platforms.

Connectivity and Telematics Systems

Telematics systems provide real-time data on truck performance, location, and driver behavior, revolutionizing fleet management. These systems, introduced in the 2000s and now widely used, enable fleet operators to monitor fuel consumption, engine health, and route efficiency, leading to cost savings and improved safety. Connectivity between trucks and fleet managers allows for predictive maintenance, reducing downtime and improving overall efficiency. Manufacturers like Daimler and Volvo offer integrated telematics systems that help companies optimize their operations.

Advanced Emission Control Systems

Emission control systems have undergone significant advancements, particularly with the introduction of Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF). These technologies, mandated by government regulations like the Euro 6 and U.S. EPA standards, drastically reduce harmful emissions such as nitrogen oxides (NOx) and particulate matter. SCR systems use a urea-based solution to convert NOx into harmless nitrogen and water, while DPFs trap and remove soot particles. These systems have allowed diesel trucks to meet increasingly strict emissions standards while maintaining power and performance.

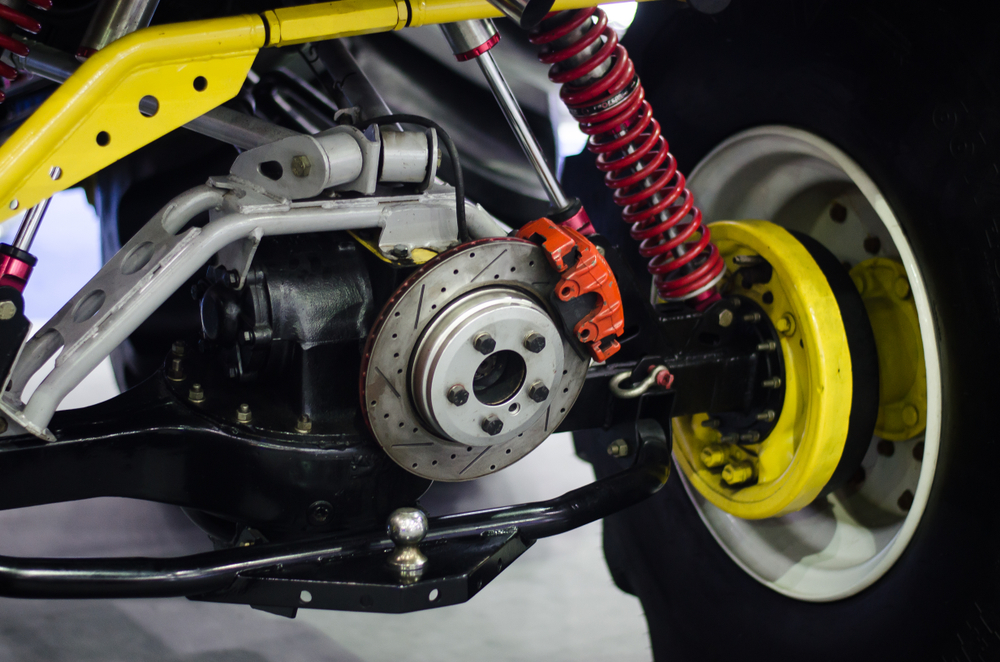

Active Suspension Systems

Active suspension systems, introduced in trucks in the 2000s, use sensors and electronically controlled dampers to adjust the suspension in real-time based on road conditions. This technology improves ride comfort, handling, and safety by reducing body roll and maintaining stability, especially when carrying heavy loads. Brands like Mercedes-Benz have incorporated active suspension into their trucks, enhancing the driving experience and reducing wear on components. Active suspension systems also reduce driver fatigue, making long hauls safer and more comfortable.

Hydrogen Fuel Cell Trucks

Hydrogen fuel cell technology is an emerging innovation in truck manufacturing, offering a zero-emission alternative to diesel and electric trucks. Companies like Nikola and Toyota are developing hydrogen-powered trucks that generate electricity from hydrogen gas, producing only water vapor as a byproduct. Hydrogen fuel cells provide longer ranges and shorter refueling times compared to electric batteries, making them ideal for long-haul trucking. As infrastructure for hydrogen refueling expands, this technology could play a key role in the future of sustainable trucking.

In-Cab Comfort and Ergonomics

The focus on in-cab comfort and ergonomics in truck manufacturing has greatly improved driver well-being and productivity. Modern trucks now come equipped with features such as adjustable air-ride seats, climate control, advanced infotainment systems, and sleeper cabs designed for long-haul drivers. Companies like Volvo and Freightliner have prioritized driver comfort, recognizing that a well-rested and comfortable driver is a safer and more efficient driver. This shift towards better ergonomics has also helped attract and retain more drivers in an industry facing labor shortages.

Over-the-Air Software Updates

Over-the-air (OTA) software updates are a recent development that allows truck manufacturers to remotely update a vehicle’s software, improving performance, safety, and functionality without requiring a trip to the service center. Companies like Tesla, Volvo, and Daimler have implemented OTA updates, enabling them to fix bugs, improve fuel efficiency, and even add new features over time. This game-changing development reduces downtime for truck operators and ensures that vehicles stay up to date with the latest technology.

Advanced Aerodynamic Features

The addition of advanced aerodynamic features to trucks has significantly improved fuel efficiency by reducing drag. Features such as roof fairings, side skirts, and rear tail fins have been integrated into truck designs to streamline airflow around the vehicle. For example, Freightliner’s Cascadia Evolution incorporates numerous aerodynamic enhancements, resulting in fuel savings of up to 7%. By reducing air resistance, these features allow trucks to maintain speed with less engine effort, improving both performance and fuel economy.

This article originally appeared in MyCarMakesNoise.

More from MyCarMakesNoise

20 Features Drivers Wish Automakers Would Eliminate

Not all car features are welcomed by drivers. Some can be more annoying than useful, adding complexity or distraction. Here are some features drivers wish automakers would eliminate to enhance the driving experience. Read More.

10 Must-Have Upgrades for Your Motorcycle

Motorcycle enthusiasts often look to aftermarket modifications to enhance the speed and performance of their bikes. Here are 10 popular aftermarket mods that can make almost any motorcycle faster, along with detailed explanations and tips for each. Read More.

The 10 Most Iconic American Supercars

Whether it’s through groundbreaking technology or iconic design, these supercars not only push the limits of speed but also embody the spirit of American ingenuity and the passion for pushing boundaries. Read More.