The crankcase ventilation system houses some of the most significant engine components. A malfunctioning or disconnected P04DB system may not seem serious, but over time it can end up damaging other components. This damage ultimately reduces the vehicle’s functionality and performance.

Read on to discover the possible causes and how to fix them.

Contents

What Does Code P04db Mean?

The P04DB is a Diagnostic Trouble Code (DTC) an engine displays when the crankcase ventilation system is disconnected, faulty, or damaged.

If left unchecked, a disconnected P04DB crankcase ventilation system can result in different forms of malfunctions, such as overheating of the engine and even a fire eruption. The P04DB code can also be displayed when the CCV system sensor reads below 2.5 volts.

Where Is the Crankcase Ventilation System

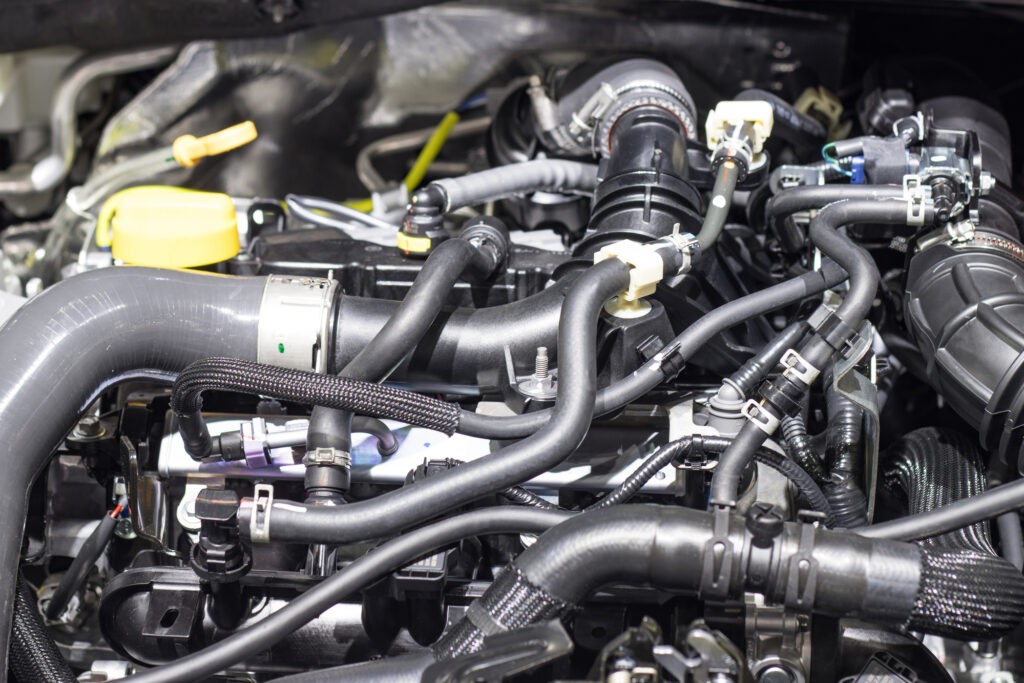

A crankcase ventilation system is the central part of a vehicle’s engine. This system comprises vital engine components such as the crankshaft, cylinders, pistons that power the engine, the inlet manifold, and so on. Bear in mind that the exact position of some of its components for one type of vehicle may be different from another.

What Does It Do?

A crankcase ventilation system is designed to help cool a vehicle’s engine. It does this by providing air to the crankcase. This airflow helps prevent excessive build-up of pressure from unwanted gasses within the engine, known as “blow-by.” This process results in cleaner combustion and optimized engine performance.

The blow-by gasses, if left unchecked, will condense and combine with oil mist or vapor in the crankcase. This issue causes layers of sludge that can harm the internal components. In addition to removing these gasses, the crankcase ventilation system captures the unwanted emissions and redirects them toward the vehicle’s intake manifold.

What Causes a P04DB Code?

The exact cause of a P04DB code will, to a large extent, depend on the generation of the vehicle. Here are some possible causes of this error code.

Disconnected Crankcase Ventilation Hose

A disconnected hose is one of the primary reasons the P04DB code displays. The hose is attached to the exhaust, and the motor uses it for temporary gas storage.

No matter the type of vehicle, if there is a bridge in the connection of the crankcase ventilation hose, it can result in many problems—hence the P04DB error.

Damaged PCV Valve

A faulty PCV may either be due to excessive use or an accumulation of unwanted emissions. One of the results of this problem is oil leakage and a reduction in fuel efficiency.

Damaged Engine Module Performance (ECM)

You are likely to get the P04DB error if your vehicle’s engine is not in proper condition. This error can be due to damage to the engine control machine (ECM). The ECM helps to examine, monitor, and regulate the function of your engine. Damage can result as a result of exposure to excessive heat or humidity.

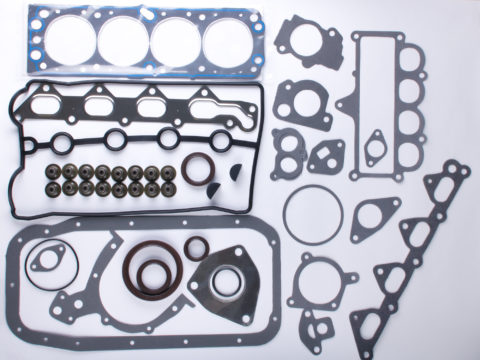

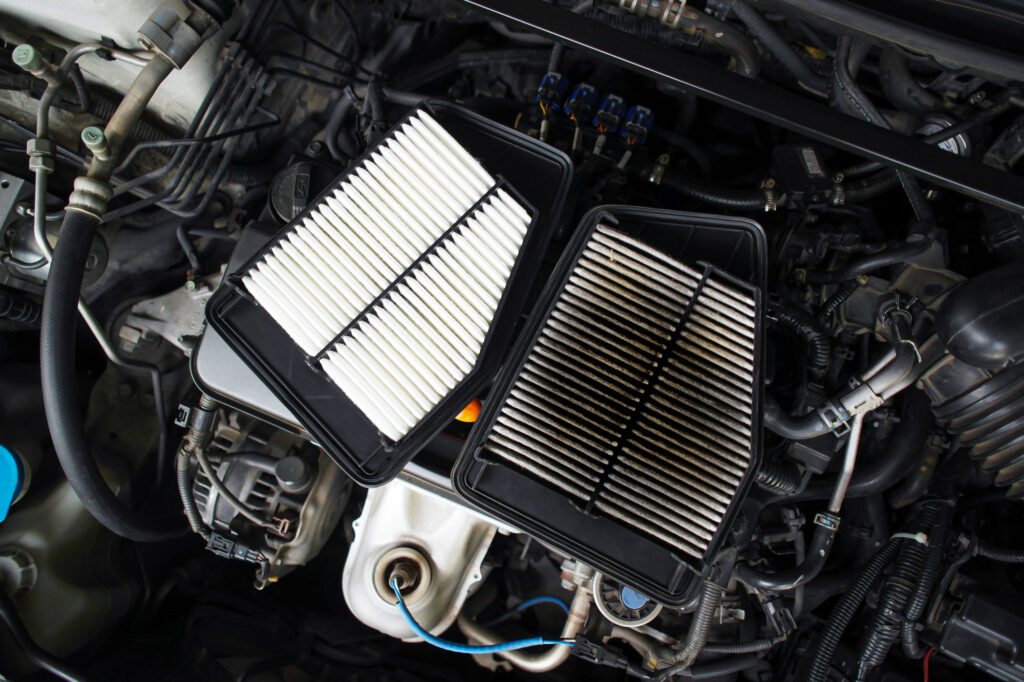

Faulty Crankcase Ventilation Filter

The crankcase ventilation filter is one of the most critical components of the entire crankcase ventilation system. Sometimes the flow passages of this filter can become faulty, due to dirt and heat, and block airflow and movement of oil.

Broken Crankcase Sensor

A crankcase position sensor is a necessary component of combustion motors. It plays a significant role in the ignition, fuel control, and performance of the motor. On the other hand, this sensor can become faulty due to broken cords. When that happens, the P04DB error displays on the onboard diagnostic scanner.

Code P04DB Symptoms To Look Out for

When the crankcase ventilation system needs some form of service, it usually displays a few symptoms to draw the driver’s attention to a possible problem. Some of the symptoms that point to a malfunction of the crankcase ventilation are as follows:

- Vehicle consumes and emits excess oil

- The engine makes more noise than usual

- The vehicle refuses to start remotely

- Vehicle accelerates poorly

- Sudden vehicle stops

- The “Check Engine” light is on

P04DB Crankcase Ventilation System Disconnected Fix

Here’s how to resolve the problem.

Replace Broken Crankcase Sensor

When a P04DB error on the onboard diagnostic scanner indicates a sensor fault, a sensor swap is the best fix. This fix will require removing its attached connector and pulling out its positioning bolt. If there are loose or malfunctioning cords, they should also be changed to stabilize the flow of voltage.

Tighten Crankcase Ventilation Hose

When the hose comes loose from the attachment area, the system will require immediate replacement or repair. A complete swap of the hose is usually a complex process. Alternatively, you can examine its attachment points for any loose nuts.

Change Faulty Crankcase Ventilation Filter

When a crankcase filter becomes faulty, it should be replaced with a new one. As a general rule, replace the filter every time a new spark plug is added for optimal motor performance.

Replace Damaged ECM

Sometimes, fixing the crankcase ventilation alone may not solve the P04BD problem when the engine control module is faulty. When you observe signs such as poor acceleration and sudden vehicle stops, you should check the engine. When the engine control module becomes damaged, it should be immediately replaced.

Replace Bad PCV

A damaged PCV will affect the performance of your vehicle. It should be replaced with a new, compatible valve. To do so, you simply loosen the old valve and remove it. After doing so, fix the new valve according to the provided guidelines and apply more oil to the fill tube.

Can You Still Drive with the P94DB Code Error?

Whether or not it’s safe to drive with the P04DB error will depend on the vehicle’s performance at the time. If there are no abnormal issues, you are safe to continue driving. Regardless, you should have it checked as soon as possible and the problem fixed to avoid it becoming more serious.

Is a Crankcase Ventilation System Necessary?

The engine of a vehicle is an assembly of different essential mechanisms and components. These components, in turn, play a unique role in the overall function of the vehicle.

For a gas-powered combustion engine, crankcase ventilation is an essential component. This component helps remove harmful vapors and blow-by gasses from the engine. More than just saving the whole machine, it also saves the environment.