You can better maintain your truck when you have intimate knowledge of how the engine works. Knowing about cylinders and firing order is a more technical understanding of engines, but understanding the number and firing order will help you troubleshoot issues such as misfiring. It’s also worthwhile just to know your engine and how it operates.

Read on for a complete guide to the 6.0 Powerstroke engine. You’ll learn a brief history of this design, the cylinder number and firing order, and some known problems to look out for.

Contents

Ford 6.0 Powerstroke Cylinders History

Ford knew it needed to phase out the previous iteration of the Powerstroke engine, the 7.3L. New emissions standards were impending. With the innovations in the 6.0 Powerstroke, Ford met the incoming set of emissions standards a year ahead of schedule. This whole new engine platform made by Navistar was ground-breaking in many ways.

During its production run from 2003-2007, the 6.0 Powerstroke gained popularity for its increased power and torque over its predecessor. It’s an 8-cylinder engine with a variable geometry turbocharger, EGR system, and advanced fuel injection. This engine appeared in the F-Series and Super Duty trucks.

It soon became clear that owning a truck with the 6.0 Powerstroke meant you would deal with a spate of problems. The engine garnered a mixed reputation among diesel drivers.

Regular maintenance and a few aftermarket upgrades take care of many possible issues with this engine.

6.0 Powerstroke Specs

- Productions years: 2003-2007

- Valvetrain: OHV, single cam, four favors per cylinder

- Bore: 3.74 inches

- Stroke: 4.13 inches

- Injectors: Siemens-electronically controlled, hydraulically activated

- High-Pressure Oil Pump: Siemens-swash plate, axial piston pump

- Displacement: 365 Ci

- Compression Ratio: 18.0:1

- Turbocharger: Garret-variable geometry turbocharger (VGT)

- Intercooler: air-to-air

- Emissions: EGR (exhaust gas recirculation) system

- HP: 325hp at 3300rpm

- Torque: 560 lb-ft at 2000rpm in 03-04 model years, 570 lb-ft at 2000rpm in 05-07 model years

- Block: cast iron

- Rods: Powdered metal

- Pistons: cast aluminum

- Heads: cast iron with 14mm head bolts, four bolts per cylinder

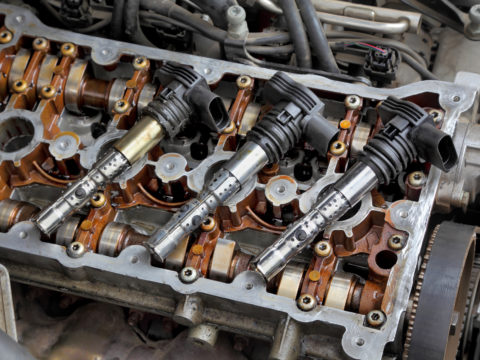

6.0 Powerstroke Cylinder Layout Diagram

Engines have several possible configurations. Cylinders fire according to a preset rotation, but the numbers are not consecutive.

How The Cylinders Are Numbered on a 6.0 Powerstroke

Ford designed this engine as a V8. That means it has 8 cylinders with 4 on each side configured in a V-shape.

Looking at the engine, you’ll see that one bank of cylinders is slightly offset from the other. This is an intentional aspect of the design so the sets of cylinders are not directly parallel.

In the 6.0 Powerstroke, the even number cylinders 2, 4, 6, and 8 are on the driver’s side. Odd number cylinders 1, 3, 5, and 7 are on the passenger side.

How Many Valves Per Cylinder Does a 6.0 Powerstroke Have?

Ford rolled out a new cylinder head configuration with this engine. This innovation also contributed to meeting new emissions standards.

The 6.0 Powerstroke engine features four valves per cylinder. Two intake valves measure 1.33 inches in diameter, and two exhaust valves measure 1.10 inches. The valves are set in a twisted orientation compared to the cylinder to increase the port swirl.

Port swirl is the air movement in the chamber as the piston travels down the bore. Swirl controls engine output and RPMs. Diesel engines depend more heavily on port swirl for efficiency than gasoline engines. This was Navistar’s first four-valve cylinder configuration.

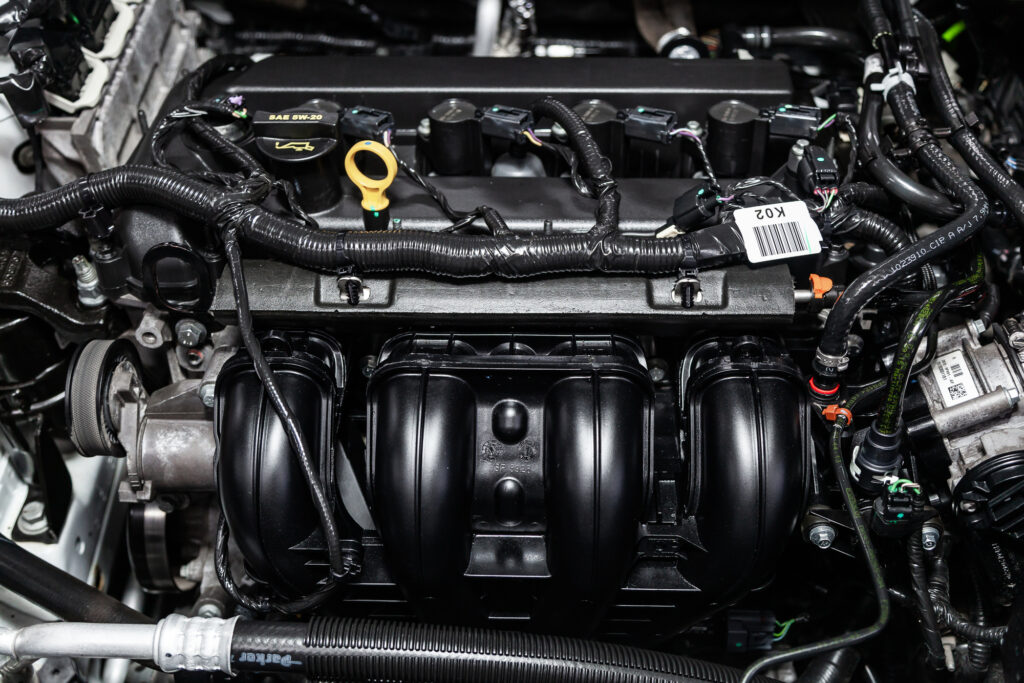

How Many Oil Pumps Are in a 6.0 Powerstroke?

The 6.0 Powerstroke requires a high-pressure oil pump for the fuel injectors to do their job efficiently. Ford outfitted this engine with one high-pressure oil pump (HPOP) situated at the rear of the valley. The rear gear train drives the oil pump.

The HPOP supplies oil volume to the fuel injectors and the injection pressure regulator. The injection regulator controls the oil pump outlet pressure and sits inside the HPOP cover.

These parts are notorious for failure in later model year 6.0 Powerstroke engines.

6.0 Powerstroke Firing Order Explained

Cylinders in any engine don’t fire in numerical order because the heat and pressure could cause the crankshaft to deform and fracture. There is a contained explosion repeating inside each cylinder every time it fires. So, engine designers disburse and balance the effects of combustion throughout the engine.

The firing order varies by engine type, cylinder number, and configuration. In an 8-cylinder engine like the 6.0 Powerstroke, there are several possibilities for firing order.

While the cylinders do not fire in numerical order, the sequence is not random. The cylinders fire in this order: 1-2-7-3-4-5-6-8. If you follow the diagram above, you can see how this order zig-zags across the two banks of cylinders. The only cylinders that fire next to each other are 6 and 8. They continue to fire repeatedly in this order while the engine is running.

Some variation in firing order is possible, so always check your owner’s manual to be sure.

Common 6.0 Powerstroke Problems

The 6.0 Powerstroke was a giant in engine innovation at the time. However, the new design that helped meet emission specifications also lead to some common issues.

Blown Head Gaskets

6.0 Powerstroke owners became familiar with head gasket issues. The number and type of bolts per cylinder play a significant role in this problem.

Each cylinder has 4 14mm torque-to-yield (TTY) bolts. TTY fasteners are commonplace in automotive engines. But, once they stretch beyond their yield point, they remain permanently elongated. The result is reduced clamping force. Four bolts per cylinder are insufficient to hold down the pressure beneath them.

There is no correlation between blown head gaskets and model year. The problem crops up randomly but doesn’t have to put you off from considering a 6.0 Powerstroke. You can upgrade to ARP head studs which are stronger than factory head bolts.

Failed Oil Cooler

The Hydraulic Electronic Unit Injector (HEUI) system circulates oil through the turbocharger and uses high-pressure oil to actuate the injector. The oil is doing lots of work in the engine causing tons of extra heat. To offset the excess heat, Ford installed an oil cooler. Oil and coolant circulate through the unit where the coolant reduces the oil temperature.

Coolant in the oil or oil in the coolant is a sign that the oil cooler has failed. Most likely, residual sand after the part was cast leads to clog and then failure.

Electronic diagnostic equipment or a digital monitor can also determine if your oil cooler has failed. Either method measures the difference between the EOT (engine oil temp) and the ECT (engine coolant temp). You should maintain less than 14 degrees difference with an OE oil cooler. For example, when the coolant is 196 degrees, you want the oil to stay at or below 210 degrees. Testing should be done at wide-open throttle for accuracy.

Changing oil and coolant according to Ford’s recommended maintenance schedule reduces the chance of oil cooler failure. You can also install an aftermarket coolant filtration system to keep the coolant clean and flowing freely.

Failing to protect the oil cooler may lead to the next common problem for 6.0 Powerstroke engines.

EGR Cooler Failure

Exhaust Gas Recirculation (EGR) is another cooling system that uses coolant to bring down the temperature of the exhaust before it leaves the tailpipe. The EGR system helps your engine meet emissions standards and protects the head gasket from building up too much pressure.

Failure in the EGR cooler typically begins with a clogged coolant filter.

FICM Failure

The fuel injection control module (FICM) withstands heat and vibration while the truck is running because it is mounted to the driver-side valve cover. You or a mechanic can check the voltage on the FICM with electronic diagnostic equipment. The module should not exceed 48 volts of output.

ICP/IPR Sensor Problems

The injection control pressure (ICP) and injection pressure regulator (IPR) are crucial for the HEUI system. When these sensors fail, it leads to problems already discussed in the oil cooling system. Sensor failure also may lead to stalling, surging, poor idling, and not starting.

You can check on the ICP sensor by removing the harness and looking for oil on the electrical terminals. If it’s oily, then the sensor has failed.

HPOP Malfunction

The high-pressure oil pump (HPOP) is another known problem for 6.0 Powerstroke engines. Earlier model years suffer from this issue more than the later ones. Mostly the problems come when O-rings and other seals wear out and leak.

Factory specifications say the oil pressure should be 3000-4000 psi at WOT. Idling pressure should read 600-700 psi. Pressure below 500 psi does not allow the injectors to fire so the engine can start. A mechanic can use a digital monitor to check the HPOP pressure.

So, Is the 6.0 Powerstroke a good engine?

Despite the known problems with the 6.0 Powerstroke, it remains popular among Diesel engine enthusiasts. Using aftermarket upgrades and replacement parts solves most of the issues presented by the innovative design of the 6.0 Powerstroke.