Formula 1 cars are more than just fast—they’re incredible feats of engineering that push the limits of technology and innovation. Behind every race is a team of engineers fine-tuning every detail to gain even the slightest advantage. From aerodynamics to engine design, there’s a lot more to these machines than meets the eye. In this article, we’ll explore 15 surprising facts about the cutting-edge engineering that makes F1 cars the fastest vehicles on the planet.

Contents

Wind Tunnel Testing

Wind tunnel testing is crucial to Formula 1 car development because aerodynamics play a massive role in speed and efficiency. Engineers simulate real-life airflows to optimize every curve and surface of the car. With hundreds of hours spent in the tunnel, teams refine the car’s shape to minimize drag and maximize downforce. Even slight improvements in airflow can shave valuable seconds off lap times. This meticulous process helps engineers understand how the car will perform under different racing conditions, making it a vital part of F1 engineering.

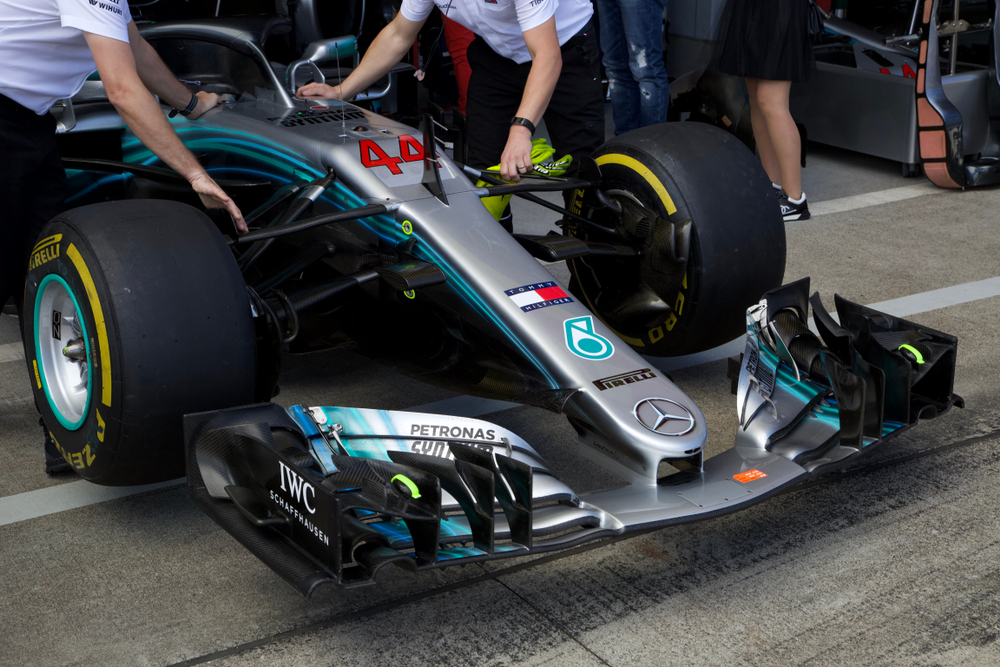

Turbulence Control

Tiny fins, called bargeboards and winglets, are added to control airflow turbulence, which can disturb the car’s balance and stability. These aerodynamic devices help channel air smoothly around the vehicle, reducing drag and enhancing grip in high-speed corners. By managing airflow in such detail, F1 engineers can improve a car’s performance on circuits with complex turns. The technology behind these fins allows for better tire grip, reduced wear, and consistent handling, providing the driver with better control, especially under extreme racing conditions.

Weight Distribution

In Formula 1, weight distribution is a delicate science, as it affects the car’s balance, acceleration, and braking. Engineers strategically place components like the engine, fuel tank, and driver’s seat to ensure optimal handling. By concentrating weight around the car’s center, they can improve overall stability, making it easier for the driver to control the car through tight corners. A car with poor weight distribution will have inconsistent handling, leading to slower lap times and increased tire wear. Balancing this weight becomes a game-changer in car performance.

Downforce Generation

Downforce is a key factor that allows F1 cars to take corners at incredible speeds. By directing air over the car to press it onto the track, downforce increases traction and grip, allowing the tires to maintain better contact with the surface. F1 cars can generate downforce equal to their weight, meaning they can theoretically drive upside-down on a ceiling if needed. This immense force improves cornering speeds and stability but must be carefully balanced with drag to avoid slowing the car down on straights.

Ultra-Light Materials

To achieve maximum speed, Formula 1 cars are made from ultra-light yet incredibly strong materials like carbon fiber. Carbon fiber composite is used in the chassis, bodywork, and even the suspension to reduce the car’s weight without compromising on durability or safety. These materials allow engineers to shave off every unnecessary gram, ensuring the car can accelerate faster and reach higher top speeds. Despite their lightness, these materials are robust enough to withstand the extreme forces and stresses encountered during a race.

Tires Made to Last Only 50 Miles

Unlike road tires, Formula 1 tires are designed for extreme grip but have a very short lifespan, usually lasting less than 50 miles. These tires provide the necessary traction to handle sharp turns and high-speed maneuvers. The compound is incredibly soft, which maximizes grip but wears down quickly under the heat and friction of racing. Engineers and strategists must carefully plan pit stops around tire degradation, as worn-out tires lead to significant drops in performance and can affect the outcome of a race.

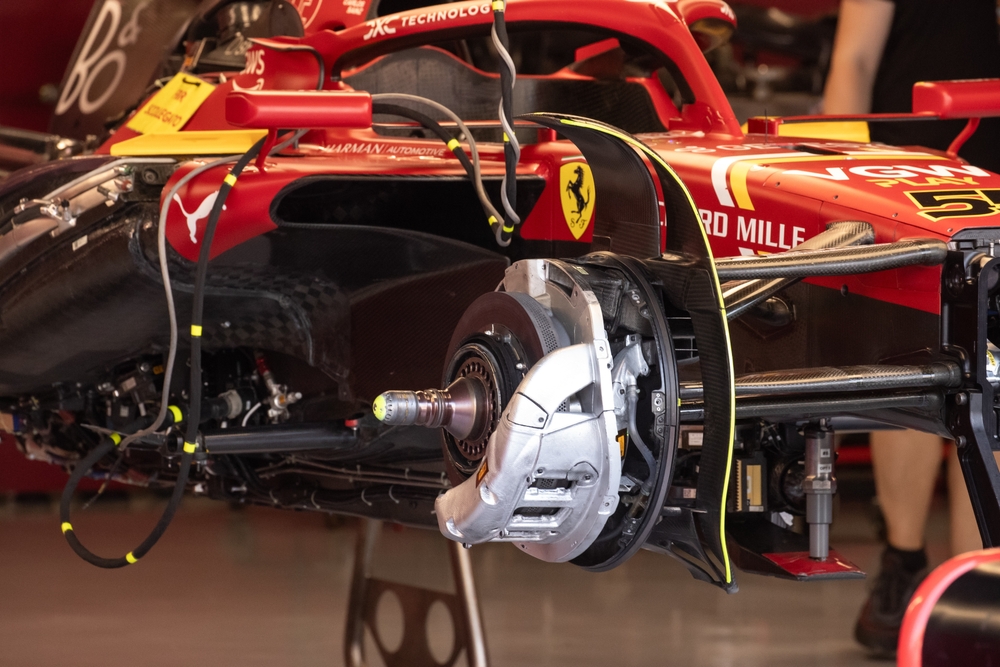

Brake Cooling

F1 braking systems reach temperatures of up to 1,000°C during a race, requiring complex cooling systems to prevent failure. Engineers design sophisticated brake ducts to direct airflow onto the brakes, dissipating heat while maintaining the necessary friction. Without effective cooling, brakes could overheat, leading to reduced performance or even complete failure. Managing brake temperature is critical, especially on circuits with heavy braking zones, where the ability to slow down quickly and efficiently can make a significant difference.

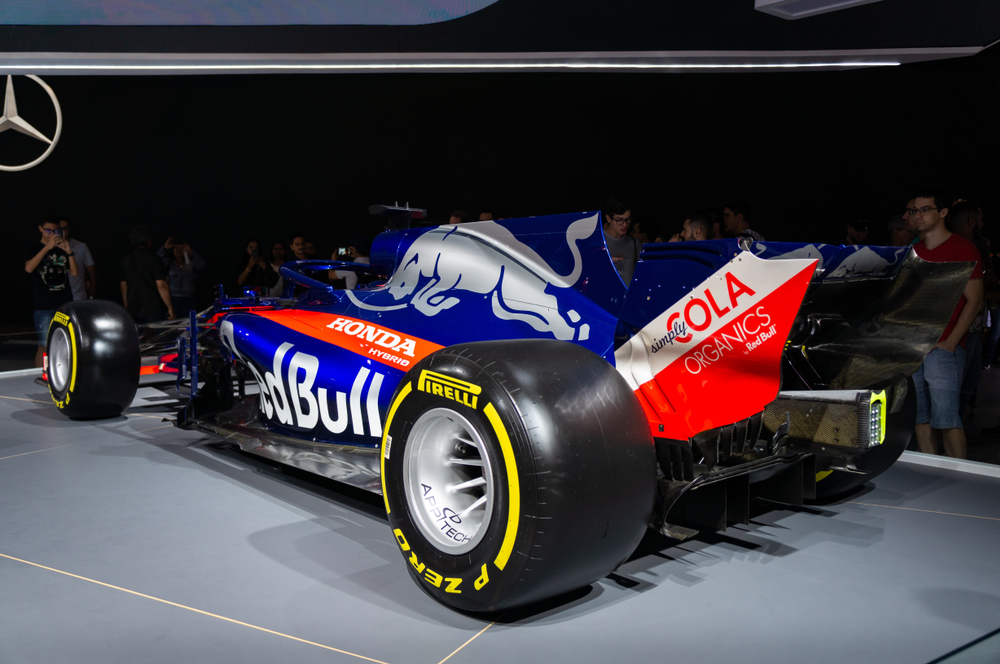

Hybrid Power Units

Modern F1 cars feature hybrid power units, combining a turbocharged V6 engine with an electric motor system. This not only improves fuel efficiency but also boosts overall power. The energy recovery systems (ERS) harness kinetic and thermal energy, storing it in batteries to provide additional horsepower during acceleration. This hybrid technology allows F1 cars to maintain top performance while adhering to strict fuel usage limits, striking a balance between speed, efficiency, and environmental responsibility.

KERS System

The Kinetic Energy Recovery System (KERS) captures energy normally lost during braking and stores it for later use. This stored energy is then released to provide an additional boost of power when the driver needs it most, such as during overtaking. KERS can add up to 160 horsepower for a few crucial seconds, giving drivers a strategic advantage in tight racing situations. The system represents a brilliant example of energy efficiency, using the car’s own momentum to improve performance.

Gear Shifts in Milliseconds

F1 cars are equipped with semi-automatic gearboxes that allow drivers to shift gears in just 0.005 seconds. This lightning-fast gear change ensures there is no interruption in power delivery, maintaining the car’s momentum and performance. The gearbox uses seamless shift technology, which means the driver can shift without lifting off the throttle, allowing for smoother transitions. These split-second shifts are crucial in maintaining peak engine performance, especially in high-speed racing situations.

Drag Reduction System (DRS)

The Drag Reduction System (DRS) is a strategic feature in F1 designed to make overtaking easier. Drivers can activate DRS to reduce the angle of the rear wing, minimizing drag and allowing the car to reach higher speeds on straights. However, DRS is only available in designated zones and under specific conditions, adding an extra layer of strategy to the race. This clever piece of engineering provides a significant speed boost but requires careful timing and execution to maximize its advantage.

Precision Steering

Formula 1 steering wheels are incredibly complex, featuring over 20 buttons and switches that allow the driver to adjust various car settings mid-race. Drivers can change brake balance, adjust fuel mixture, control tire management systems, and even communicate with their teams via the steering wheel. This level of control allows them to fine-tune the car’s performance for different sections of the track or adapt to changing conditions. The precision and versatility of the F1 steering system enable drivers to optimize every aspect of their race.

Carbon Fiber Brakes

F1 cars use carbon fiber brakes, which are both lightweight and capable of withstanding extreme temperatures. Carbon fiber is an ideal material for this purpose because it is heat-resistant and ensures high levels of braking performance even after prolonged use. These brakes provide better stopping power compared to traditional steel brakes, allowing drivers to brake later and maintain higher speeds for longer. The advanced materials and design of these brakes are critical in helping drivers control the car during high-speed races.

Fuel Efficiency

Despite the incredible speeds F1 cars achieve, they are surprisingly fuel-efficient, thanks to advanced engine technology and hybrid systems. With strict fuel regulations limiting cars to 100 kilograms (about 130 liters) of fuel per race, engineers must design engines that deliver maximum power while conserving fuel. This balance between speed and efficiency is one of the many engineering challenges in F1, where every drop of fuel counts. Achieving such efficiency without sacrificing performance highlights the cutting-edge technology behind F1 engines.

Tire Pressure Monitoring

Maintaining the right tire pressure is crucial for maximizing grip, performance, and tire longevity in F1. Engineers use tire pressure monitoring systems to track tire temperatures and pressures in real-time, adjusting settings to ensure optimal contact with the track. Under-inflated or over-inflated tires can significantly affect a car’s handling and speed, leading to decreased performance or even dangerous blowouts. Constant monitoring allows teams to fine-tune tire settings during a race, giving them a performance edge.

This article originally appeared in MyCarMakesNoise.

More from MyCarMakesNoise

18 RV Innovations That Transformed Road Travel Comfort

RV travel has come a long way in terms of comfort and convenience, thanks to a range of innovative features that make life on the road easier. From advanced power systems to smart technology, these innovations enhance the overall experience, whether you’re camping off-grid or driving cross-country. Read More

15 Vehicle Tech Concepts That Promise Much but Deliver Little

Not every idea that sounds innovative turns out to be practical. In the automotive world, many technologies and features promise convenience, safety, or efficiency but fall short when put to the test. Read More

14 RV Models That Defined the Golden Age of Road Trips

The golden age of road trips brought with it a wave of iconic RVs that made travel more comfortable, adventurous, and accessible. These RV models, each with their unique features, helped define a generation of cross-country explorers, offering both style and practicality. Read More