Maintaining a boat engine can seem straightforward, but several unexpected problems can arise that could lead to costly repairs if not addressed early. From propeller damage to corroded electrical connections, boat engines are exposed to harsh marine environments that cause wear and tear over time. Regular maintenance is essential, but knowing what to look for beyond the obvious can save boat owners from major issues down the line.

Many boaters overlook common yet critical areas like clogged fuel systems or oil leaks, which can gradually undermine engine performance. Ignoring these problems may lead to reduced efficiency, unexpected breakdowns, or even dangerous situations on the water. Proactive care and attention to these hidden issues ensure a safer and smoother boating experience while keeping repair costs in check.

Contents

Propeller Damage

Propeller damage is a common issue for boat engines, often caused by striking underwater debris or running aground. Even minor dents or scratches on the propeller can reduce efficiency, leading to poor fuel economy and vibrations that strain the engine. Regular inspections and prompt repairs can prevent further damage to both the propeller and the engine. Left unchecked, a damaged propeller can result in reduced performance, increased wear on other components, and costly repairs. Ensuring the propeller is in good condition is crucial for smooth and safe boating experiences.

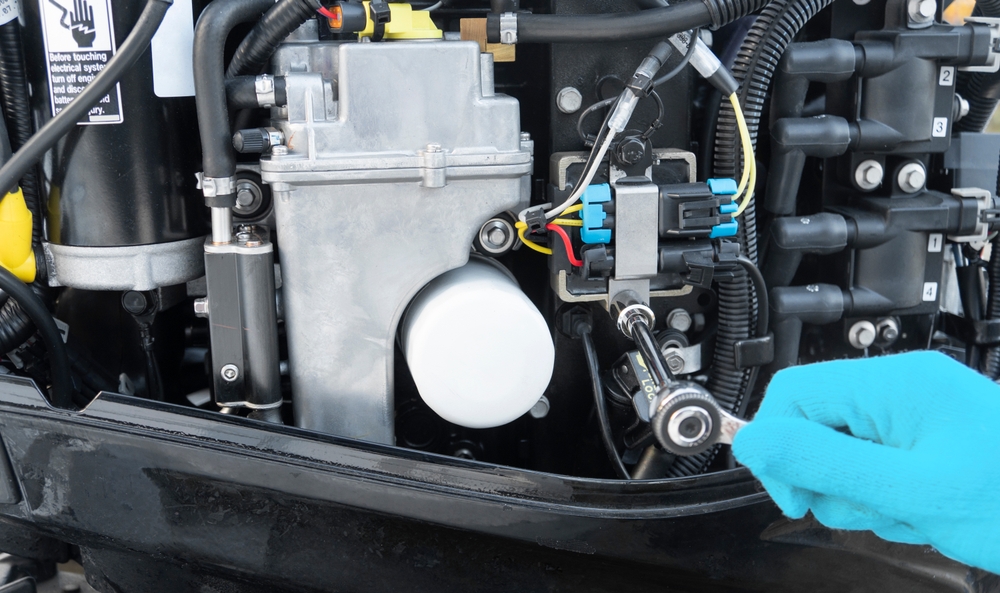

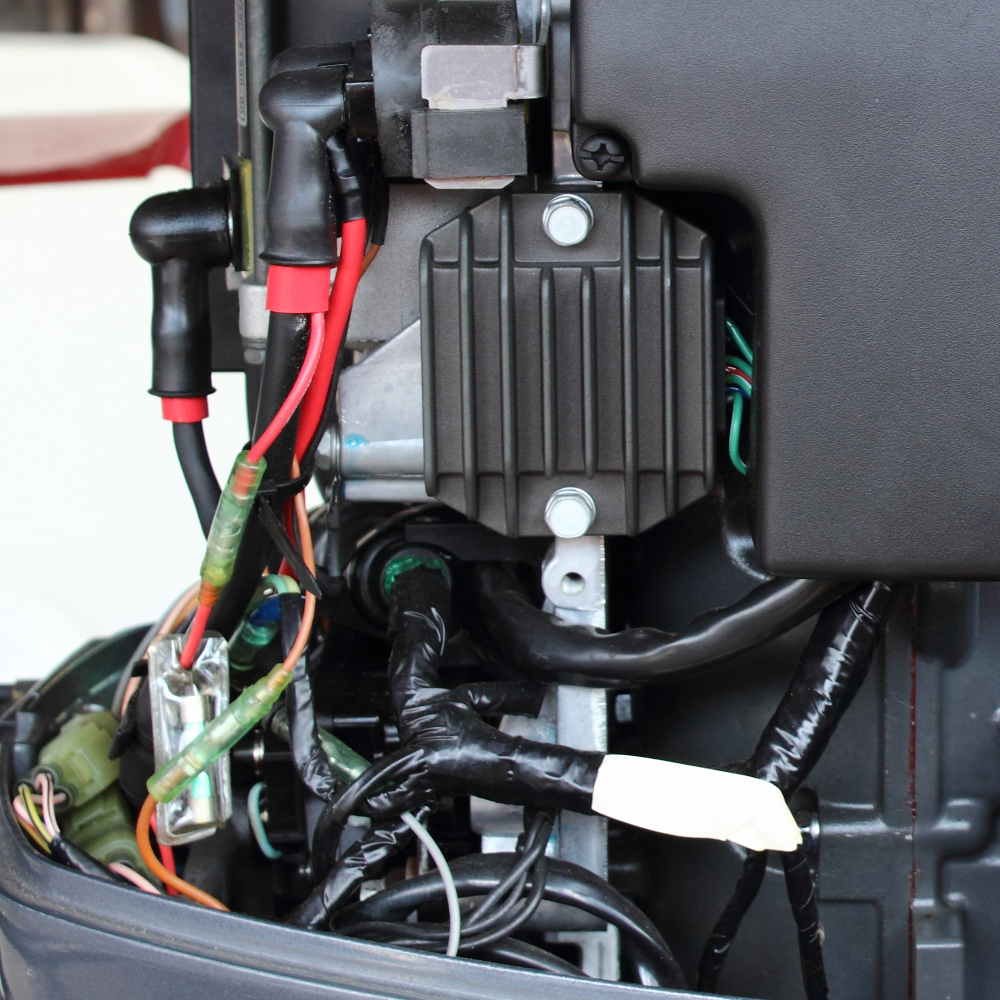

Corroded Electrical Connections

Corroded electrical connections are a major concern for boat owners, as exposure to saltwater and moisture can quickly lead to corrosion. Corrosion affects the electrical system’s ability to deliver power efficiently, leading to issues like engine starting problems or intermittent electrical failures. Routine cleaning and protection of electrical connections with corrosion-resistant coatings can prevent this issue. Without proactive maintenance, corroded connections can cause more severe electrical failures, leading to expensive repairs and unsafe boating conditions.

Fuel Contamination

Fuel contamination occurs when water, dirt, or microbial growth infiltrates the fuel tank, often resulting from improper storage or condensation in the tank. Contaminated fuel can cause poor engine performance, stalling, or even complete engine failure. Regularly checking and replacing fuel filters, using fuel stabilizers, and ensuring proper tank maintenance can help avoid these issues. Failing to address fuel contamination can lead to clogged injectors and damaged engine components, resulting in costly repairs and extended downtime.

Oil Leaks

Oil leaks in boat engines are often subtle but can lead to significant damage if not addressed early. Leaking oil can harm other engine components, cause environmental hazards, and reduce lubrication, which increases friction and wear. Regularly inspecting the engine for signs of leaks and maintaining proper oil levels can prevent extensive damage. Proactively addressing oil leaks helps maintain engine performance and prevents the need for expensive repairs caused by engine overheating or failure.

Ignition System Faults

Ignition system faults can be tricky to diagnose but are critical for engine performance. Problems with spark plugs, coils, or wiring can lead to misfires, poor fuel economy, or difficulty starting the engine. Regular inspections of the ignition system and timely replacement of worn-out components can prevent these issues. Ignoring ignition system faults can cause engine wear and lead to more costly repairs, impacting the overall safety and reliability of the boat.

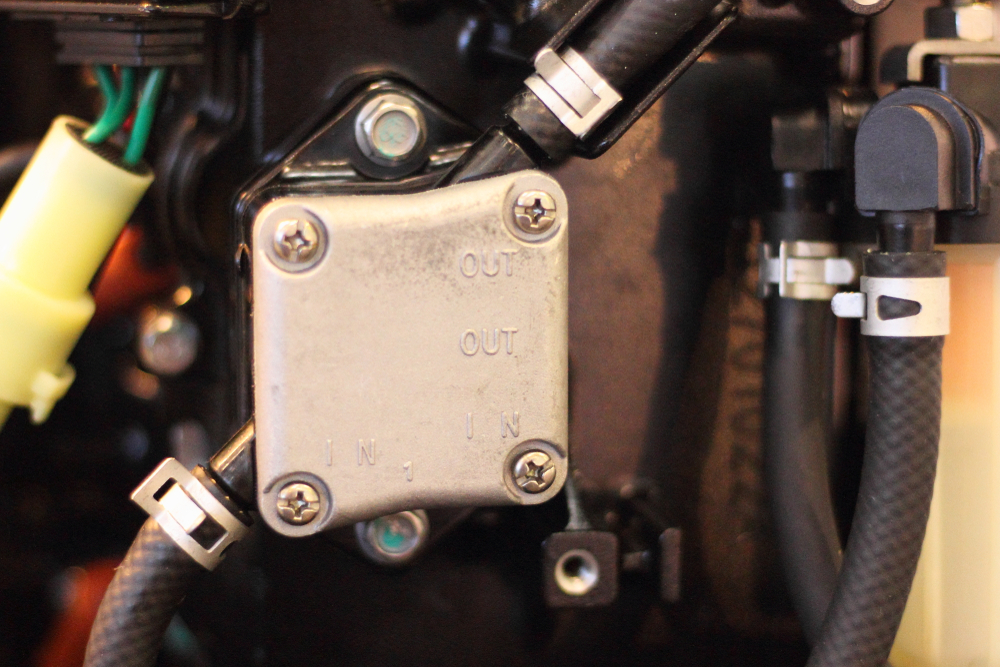

Clogged Fuel System

A clogged fuel system can severely affect engine performance, often caused by dirt, debris, or fuel deposits in the fuel lines or filters. This results in restricted fuel flow, causing the engine to run poorly, lose power, or even stall. Regular maintenance of the fuel system, including cleaning or replacing fuel filters and fuel lines, can prevent clogging. Neglecting this issue can lead to major engine damage and costly repairs, making it crucial to address fuel system blockages early.

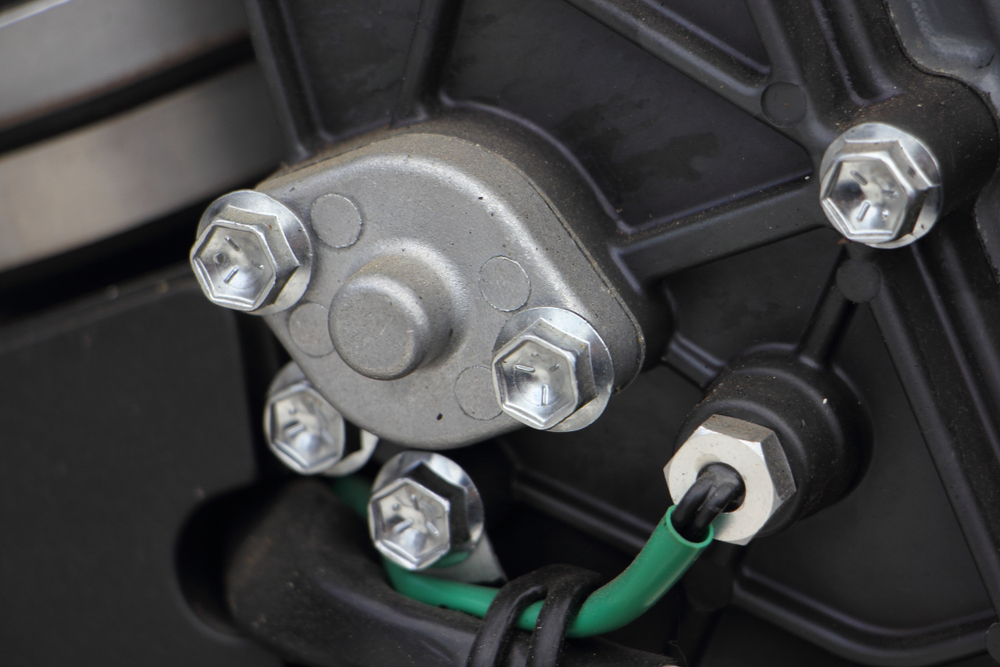

Leaking Stuffing Box

The stuffing box, which seals the shaft where it exits the boat, is prone to leaking over time. If left unchecked, a leaking stuffing box can allow water to seep into the boat, potentially causing flooding and damage to other components. Regular inspection and tightening or repacking of the stuffing box can prevent leaks. Ignoring a leaking stuffing box can lead to severe water damage, expensive repairs, and dangerous situations out on the water.

Overheating Issues

Overheating is a frequent problem in boat engines, often caused by blocked water intakes, faulty water pumps, or low coolant levels. Overheating can lead to engine failure or irreversible damage if not addressed immediately. Regularly inspecting the cooling system, ensuring proper coolant levels, and keeping water intake clear can prevent overheating. Failure to monitor this issue can result in costly engine repairs or even replacement, making proactive maintenance essential.

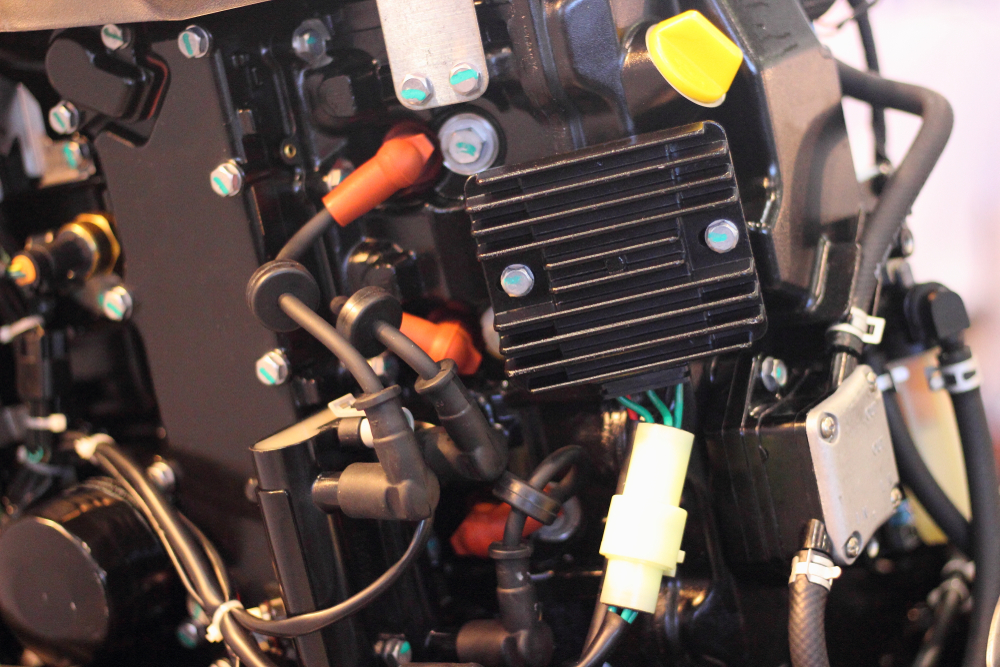

Faulty Alternator

A faulty alternator can cause charging problems for your boat’s electrical system, leading to a dead battery or malfunctioning electronic equipment. The alternator is crucial for maintaining power to the engine and other electrical systems. Regular checks of the alternator’s performance can help prevent charging failures and avoid being stranded. A failing alternator that goes unnoticed can cause expensive electrical system repairs and compromise the boat’s overall performance.

Water in the Engine

Water intrusion into the engine can be disastrous, often caused by failed seals, improper storage, or damage to exhaust systems. Water can quickly corrode engine parts, ruin fuel injectors, and lead to complete engine failure. Keeping seals in good condition and ensuring proper storage techniques can prevent water from entering the engine. Ignoring water ingress can lead to extensive engine damage, requiring costly repairs or replacement.

This article originally appeared on MyCarMakesNoise.

More from MyCarMakesNoise

18 Myths About Premium Gasoline You Need to Stop Believing

Many drivers assume premium gasoline is always the better choice, but that’s not always true. From claims of better performance to improved fuel economy, plenty of myths surround this high-octane option. Read More.

8 Famous Limousines from Hollywood Blockbusters

Limousines have long been a symbol of luxury and power, making them the perfect vehicles for memorable moments in Hollywood blockbusters. From sleek, high-tech rides to extravagant, custom designs, these limos add flair and character to the films they appear in. Read More.

10 Vintage RVs That Collectors Tend to Pass Over

Collecting vintage RVs can be a rewarding hobby, but not every model gets the same attention. Some are often overlooked by collectors, whether due to their design, maintenance challenges, or lack of modern appeal. Read More.