Modern aircraft are marvels of engineering, combining advanced technologies, materials, and design principles to create machines that are safer, more efficient, and more capable than ever before. The journey from the early days of aviation to the present has been one of continuous innovation, driven by the need to improve performance, reduce environmental impact, and meet the growing demands of global air travel. From the wings that slice through the sky to the jet engines that power these massive vehicles, every aspect of an aircraft is the result of meticulous design and cutting-edge technology.

Engineering breakthroughs have transformed modern aircraft, with innovations ranging from composite materials to sophisticated avionics and groundbreaking propulsion systems. These advancements demonstrate how engineers continuously push the boundaries of what is possible, creating designs that enhance performance, fuel efficiency, and safety. Each breakthrough not only elevates the flying experience but also addresses critical concerns such as sustainability, ensuring that aviation remains at the forefront of technological progress.

Contents

Wing Design and Aerodynamics

Modern wing designs have revolutionized aircraft efficiency by enhancing lift, reducing drag, and improving fuel consumption. Advanced shapes like the swept-back wings, winglets, and blended wing-body designs are essential for reducing turbulence and drag, allowing aircraft to fly faster and farther on less fuel. These innovations balance the need for speed, fuel economy, and stability, showcasing a delicate interplay between structural integrity and aerodynamic efficiency. Wing design continues to evolve with computational fluid dynamics and wind tunnel testing, ensuring cutting-edge performance.

Avionics Systems

The avionics in modern aircraft play a pivotal role in navigation, communication, monitoring, and overall flight control. Today’s avionics systems integrate GPS, weather radar, autopilot, and collision avoidance systems, enabling precise navigation and improving safety. The sophistication of avionics has transformed cockpits into advanced control hubs, allowing pilots to manage more complex flights with less effort. Additionally, these systems help optimize flight paths, reduce fuel consumption, and minimize human error, showcasing engineering at the intersection of safety, automation, and operational efficiency.

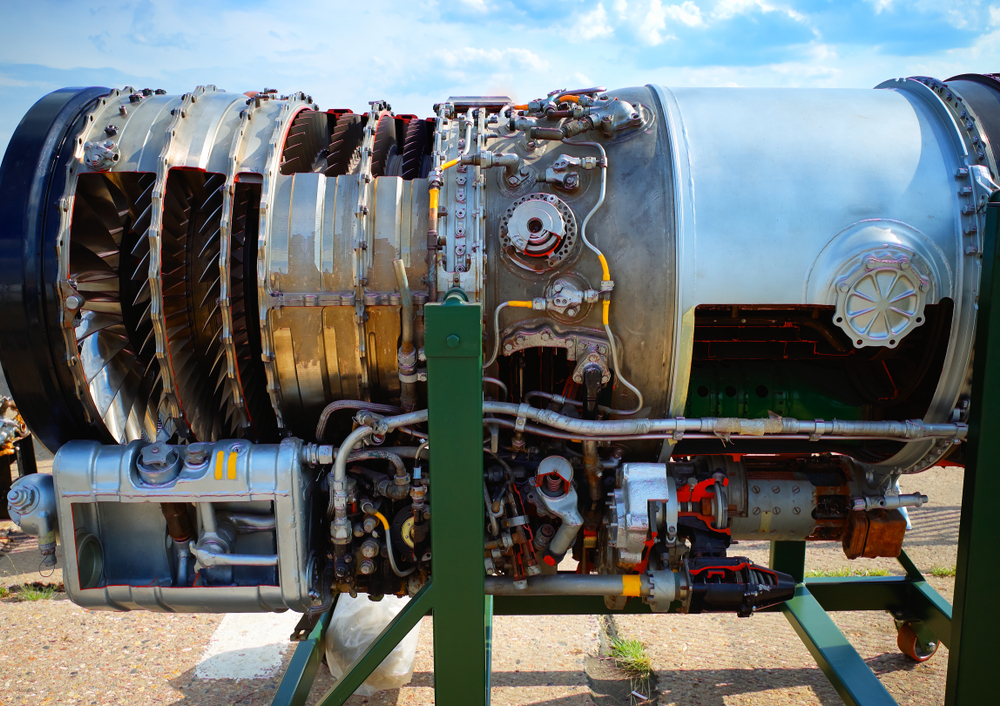

Jet Engines

Jet engines have seen tremendous advancements, from turbojets to modern turbofans, significantly improving thrust-to-weight ratios while reducing fuel consumption and emissions. High-bypass turbofan engines, which dominate today’s commercial aviation, offer greater efficiency by using a large fan to move air around the core, improving overall propulsion efficiency. Innovations such as ceramic composites, advanced cooling techniques, and 3D-printed components have also allowed engines to operate at higher temperatures, providing more power without sacrificing longevity, and demonstrating engineering ingenuity in performance and sustainability.

Composite Materials

Composite materials, such as carbon fiber-reinforced polymers, have transformed aircraft construction, allowing for lighter, stronger, and more durable structures. These materials offer superior strength-to-weight ratios compared to traditional metals like aluminum, significantly reducing aircraft weight while maintaining or even improving structural integrity. The result is lower fuel consumption, better performance, and reduced environmental impact. The Boeing 787 Dreamliner and Airbus A350 are prime examples of the extensive use of composites, showcasing a leap forward in material science that continues to drive aircraft innovation.

Fly-by-Wire Technology

Fly-by-wire technology replaced traditional mechanical flight controls with electronic systems, enhancing the precision and safety of aircraft operations. In fly-by-wire systems, pilot inputs are translated into electronic signals that are processed by computers to control the aircraft’s flight surfaces. This allows for smoother, more accurate control and includes automatic adjustments to prevent dangerous maneuvers like stalls. Fly-by-wire also reduces the weight of mechanical components and increases aircraft efficiency, reflecting the cutting-edge integration of electronics and software in modern aviation.

Supercritical Wings

Supercritical wing designs are another breakthrough in aerodynamics, allowing aircraft to fly at higher speeds without suffering from the increased drag associated with supersonic airflow. These wings flatten the upper surface of the wing, delaying the onset of shock waves and reducing wave drag, which occurs near the speed of sound. This innovation enables more efficient cruising at high subsonic speeds, a critical factor in long-haul flights, and showcases how engineering is continuously optimizing aircraft for maximum speed and efficiency.

Blended Wing-Body Designs

Blended wing-body (BWB) designs blur the line between fuselage and wing, creating a single, unified structure that offers significant aerodynamic advantages. By reducing drag and distributing lift more evenly, BWB aircraft promise to deliver much higher fuel efficiency and payload capacity than traditional designs. While not yet mainstream, ongoing research and prototypes – like the NASA and Boeing X-48 – demonstrate the potential for a radical shift in commercial aircraft design, highlighting how engineering continues to challenge the conventional in pursuit of optimal performance.

Variable Geometry Engines

Variable geometry engines can adjust their configurations in flight to optimize performance across a range of speeds and altitudes. Such engines, common in military aircraft, alter the airflow through the engine to improve efficiency in different flight conditions, from takeoff to supersonic cruise. This capability allows aircraft to achieve both high performance and fuel efficiency in varying operational scenarios. Variable geometry engines showcase the sophisticated engineering needed to balance power, speed, and efficiency in modern aircraft design.

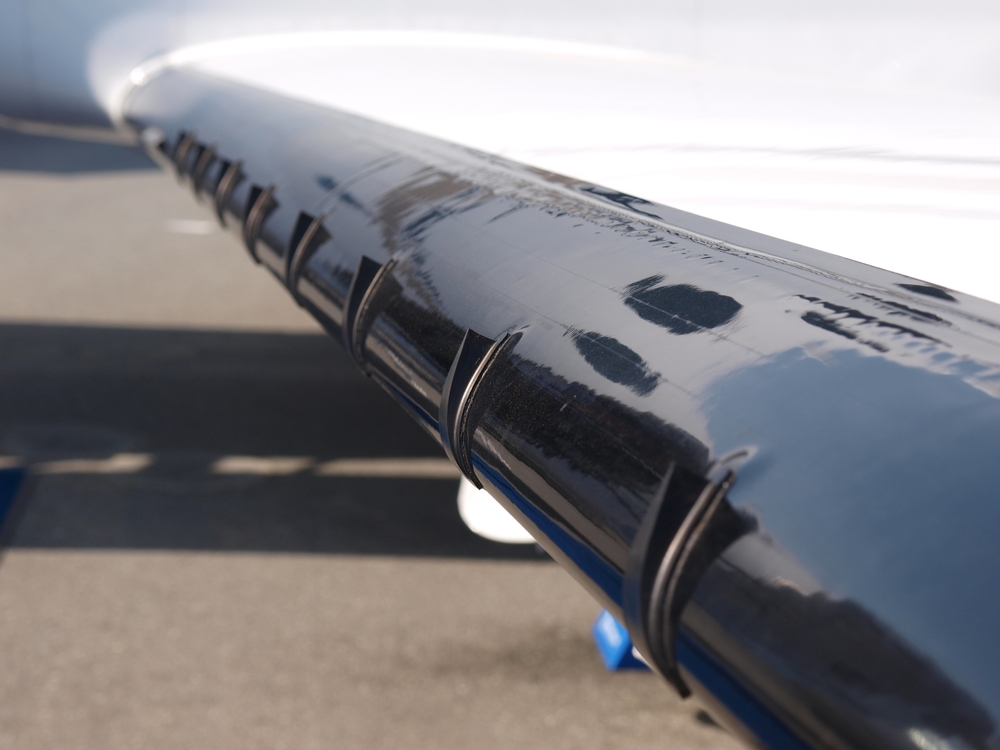

Advanced De-Icing Systems

De-icing systems have seen significant advancements, enhancing flight safety in adverse weather conditions. Modern aircraft are equipped with electric or pneumatic systems that can detect and eliminate ice formation on wings and control surfaces in real time. These systems ensure that the aircraft maintains lift and control, preventing dangerous conditions caused by ice buildup. This represents engineering innovation in safety-critical areas, enabling aircraft to operate reliably in a wide range of environments and weather conditions.

High-Bypass Turbofan Engines

High-bypass turbofan engines have revolutionized fuel efficiency and noise reduction in modern jet propulsion. By directing a large volume of air around the core of the engine, they generate more thrust using less fuel, particularly at cruising speeds. These engines are a staple in commercial aviation due to their efficiency and reduced environmental footprint, contributing to more economical and sustainable air travel. This feat of engineering continues to evolve, with each generation achieving better performance and lower emissions.

This article originally appeared on MyCarMakesNoise.

More from MyCarMakesNoise

20 Discontinued Diesel Cars That Should Return to the Market

Diesel cars have long been celebrated for their fuel efficiency, torque, and durability, but over the years, many models have been discontinued despite their loyal followings. These vehicles offered a unique driving experience, combining power with economic fuel consumption. Read More.

20 Classic Pickup Trucks with Unstoppable Inline-Six Engines

Classic pickup trucks equipped with inline-six engines are renowned for their durability, simplicity, and power. These engines, known for their smooth operation and impressive torque, made these trucks ideal for heavy-duty tasks while maintaining reliability on the road. Read More.

15 Least Fuel-Efficient Cars Ever Produced

Certain automobiles are renowned for prioritizing raw power and luxury over fuel efficiency. Equipped with massive engines and designed for high performance or ultimate comfort, these vehicles exemplify significantly higher fuel consumption. Read More.