Improper brake maintenance can lead to costly repairs if not addressed in time. Common mistakes include ignoring worn brake pads, failing to check brake fluid levels, and neglecting to replace old brake lines or rotors. Skipping regular inspections can cause minor issues to escalate, such as warped rotors or damage to the calipers. Poor-quality replacement parts or improper installation can also compromise the braking system’s efficiency, leading to expensive fixes and safety risks. Regular maintenance is essential to keep the brake system functioning correctly and avoid high repair costs.

Contents

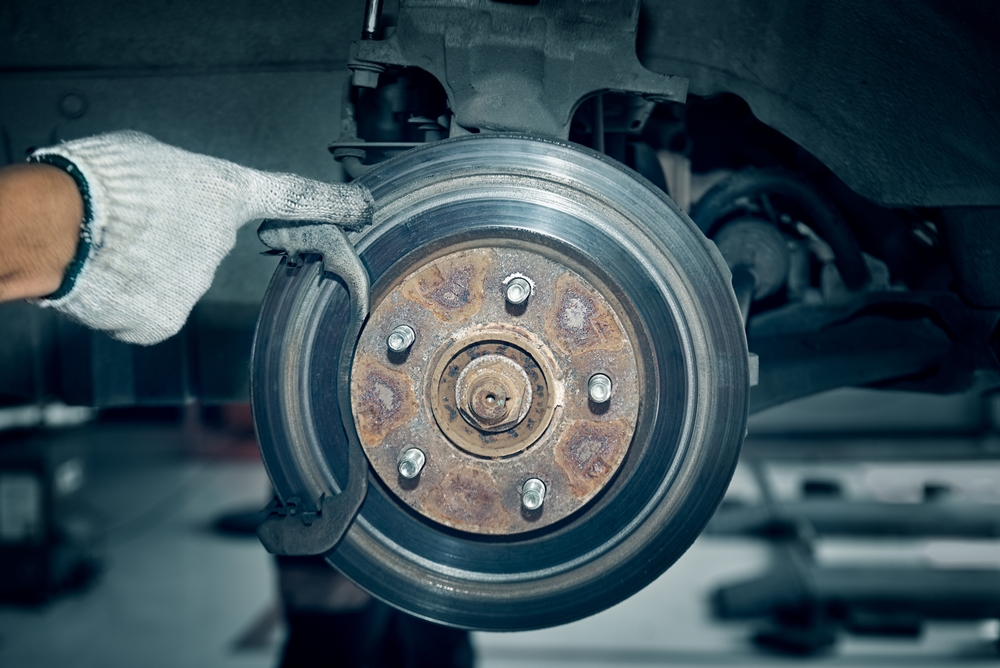

Ignoring Brake Pad Wear

One of the most common brake maintenance errors is neglecting to check for worn brake pads. Brake pads naturally wear down over time, and if they become too thin, they can cause metal-on-metal contact between the brake rotor and caliper. This results in deep grooves or scoring on the rotors, requiring expensive rotor replacement. To avoid this, regularly inspect the brake pads and replace them when they reach the minimum thickness recommended by the manufacturer (usually around 3-4mm). If you hear squealing or grinding noises, it’s a sign that the pads are dangerously worn and need immediate replacement.

Not Flushing Brake Fluid

Brake fluid absorbs moisture over time, which reduces its effectiveness and can lead to corrosion in the brake system. Failing to replace the brake fluid regularly can cause components like the master cylinder, calipers, or brake lines to corrode, leading to leaks and brake failure. This can result in expensive repairs or, worse, a complete brake system overhaul. Manufacturers typically recommend flushing brake fluid every two years or 30,000 miles. Regularly check the color of the brake fluid; if it appears dark or cloudy, it’s time for a replacement.

Neglecting Rotor Resurfacing

When replacing brake pads, it’s important to also inspect the rotors. Over time, rotors can develop grooves or become warped from heat. If these imperfections are not addressed, new brake pads may not contact the rotor surface evenly, leading to vibrations or uneven braking. This can cause premature wear of both the pads and the rotors, necessitating more frequent and costly repairs. Resurfacing or replacing rotors during a brake job ensures optimal brake performance and longevity.

Using Incorrect Brake Pads

Installing the wrong type of brake pads for your vehicle or driving style can lead to reduced braking efficiency and premature wear. For instance, using soft organic pads on a heavy vehicle can lead to quick wear, while hard metallic pads may cause rotor damage if used inappropriately. Choosing brake pads that match your vehicle’s specifications and driving conditions is critical. For high-performance or towing vehicles, consider semi-metallic or ceramic brake pads that provide better heat resistance and longer life.

Improperly Bleeding Brake Lines

Air in the brake lines can lead to spongy brakes and reduced stopping power. If brake lines are not properly bled after fluid replacement or repairs, it can compromise the entire braking system’s effectiveness. Failing to bleed brakes correctly can also lead to uneven braking, which may result in accidents. Always follow the manufacturer’s guidelines when bleeding brakes and ensure that all air bubbles are removed from the brake lines.

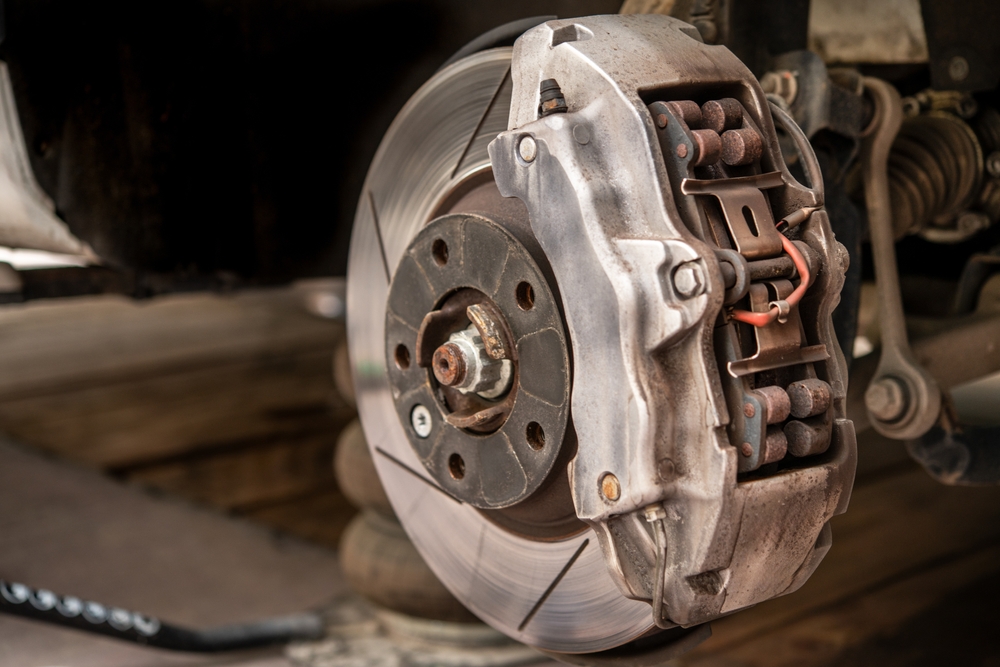

Not Replacing Worn Calipers

Brake calipers are responsible for applying pressure to the brake pads, but over time, they can become seized or leak fluid. Ignoring worn or malfunctioning calipers can lead to uneven braking, pulling to one side, or complete brake failure. Caliper issues can also cause premature pad and rotor wear. Regularly inspect the calipers for signs of rust, corrosion, or leaking fluid, and replace them if they are no longer functioning correctly. Properly maintained calipers can prevent costly repairs down the line.

Ignoring Brake Warning Lights

Many modern vehicles are equipped with brake system warning lights that indicate when there’s an issue, such as low brake fluid or worn brake pads. Ignoring these warning lights can lead to further damage and expensive repairs. If the brake warning light illuminates, have the vehicle inspected immediately to prevent potential system failure. Addressing the problem early can save on major repair costs and help avoid dangerous driving conditions.

Skipping Brake Inspections

Routine brake inspections are essential for spotting potential problems before they turn into costly repairs. Failing to regularly inspect the brake system—such as checking for worn pads, damaged rotors, or leaking brake lines—can lead to significant wear and damage over time. Most professionals recommend having your brakes inspected at least once a year or during routine tire rotations. This proactive approach can prevent small issues from escalating into expensive repairs or even brake system failure.

Improperly Adjusting Parking Brakes

The parking brake plays a critical role in keeping your vehicle stationary when parked, especially on inclines. If the parking brake is not properly adjusted, it can cause excessive wear on the rear brakes or even lead to brake system failure. Failing to use the parking brake regularly can also lead to it becoming seized, requiring costly repairs. Always engage the parking brake when parking and have it adjusted periodically to ensure it’s functioning correctly.

Failing to Lubricate Brake Components

Neglecting to lubricate brake components such as the caliper pins, backing plates, and hardware can cause sticking or uneven brake wear. Without proper lubrication, the caliper may not move freely, leading to uneven pad wear, excessive heat buildup, and eventual damage to the rotors and calipers. Use high-temperature brake grease during brake pad changes and inspections to keep all moving parts functioning smoothly. This simple step can extend the life of your brake components and prevent costly repairs.

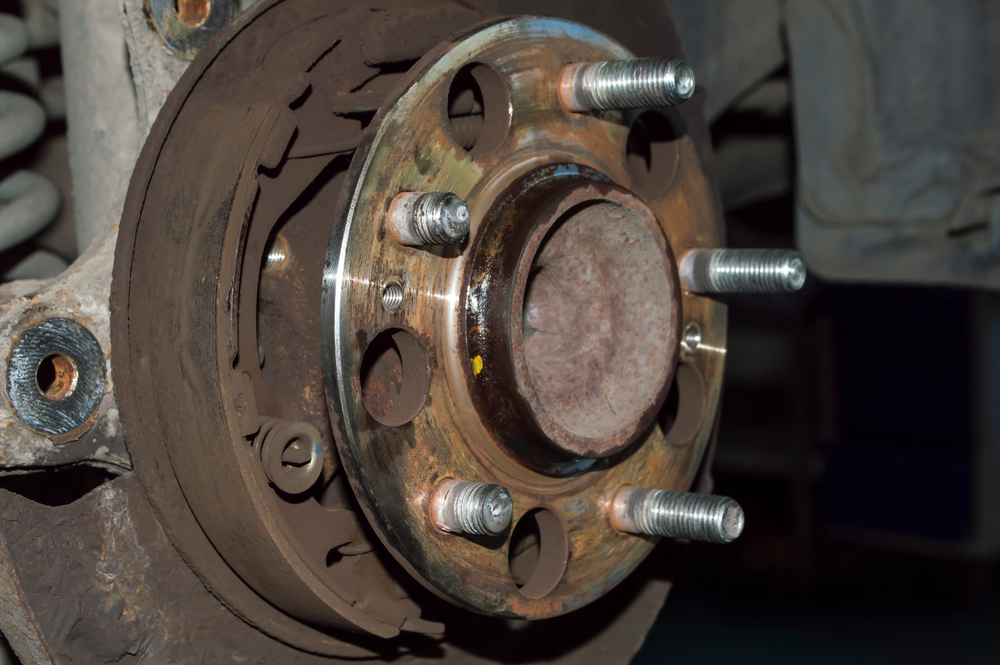

Over-Torquing Lug Nuts

Over-tightening lug nuts when reinstalling wheels after brake service can cause rotor warping and uneven wear. This can lead to vibrations during braking, reduced braking performance, and eventually necessitate rotor replacement. Always use a torque wrench to tighten lug nuts to the manufacturer’s recommended specifications. Proper torque ensures even pressure on the brake rotors and extends the life of the braking system.

Ignoring Brake Noises

Squealing, grinding, or clicking noises during braking are signs of potential issues within the brake system. Ignoring these sounds can lead to further damage, such as completely worn brake pads, damaged rotors, or failing calipers. Grinding often indicates metal-on-metal contact, which means the pads are completely worn down and could damage the rotors. At the first sign of unusual brake noise, have the system inspected to avoid expensive repairs down the road.

Failing to Replace Brake Hardware

Brake hardware, such as shims, clips, and springs, help keep the brake pads in place and ensure smooth operation. Worn or corroded brake hardware can cause the pads to wear unevenly or make noise. Failing to replace these small components when performing brake maintenance can lead to premature wear of the pads and rotors. Always replace brake hardware during a brake job to ensure optimal performance and reduce the likelihood of costly repairs.

Incorrectly Installing Brake Pads

Incorrect installation of brake pads—such as reversing the inner and outer pads or failing to properly seat them—can result in uneven wear, brake noise, and damage to other components like rotors and calipers. Incorrectly installed pads can also reduce braking performance and increase the risk of accidents. Always follow the manufacturer’s guidelines or have a professional perform the installation to ensure the brake pads are fitted correctly.

Overheating the Brakes

Overheating the brakes, especially during long downhill drives or repeated hard braking, can cause the brake fluid to boil and lead to brake fade. This results in reduced braking power and can damage components like the rotors, calipers, and pads. To prevent overheating, use engine braking on steep descents, avoid excessive heavy braking, and ensure the brake system is properly maintained. Upgrading to performance brake pads or rotors can also help dissipate heat more effectively.

Using the Wrong Brake Fluid

Using the wrong type of brake fluid can lead to brake system failure. Different vehicles require different brake fluid types (DOT 3, DOT 4, or DOT 5), and mixing incompatible fluids can cause the brake fluid to become ineffective. This leads to spongy brakes, corrosion, or even brake system failure. Always check your vehicle’s manual to ensure you are using the correct type of brake fluid, and never mix different fluid types.

Not Replacing Worn Brake Lines

Brake lines are susceptible to corrosion, especially in areas with harsh winter conditions or where salt is used on the roads. Ignoring worn or corroded brake lines can result in brake fluid leaks, which compromise the entire system. A loss of brake fluid can lead to brake failure and cause damage to other components. Inspect brake lines regularly, especially in older vehicles, and replace any that show signs of wear or corrosion.

Skipping Rotor Replacement

Worn or warped rotors can significantly reduce braking performance and lead to vibrations or noises during braking. If the rotors are not replaced when necessary, they can cause uneven wear on the brake pads, increase stopping distances, and lead to expensive repairs of the entire braking system. Always check the rotor thickness and condition during brake pad replacements, and replace or resurface them when they fall below the manufacturer’s minimum specifications.

Not Cleaning New Rotors Before Installation

New rotors are often coated with a protective oil to prevent rust during shipping. Failing to clean this oil off before installation can cause the brakes to be less effective, as the oil prevents the pads from properly gripping the rotor. This can lead to reduced braking power and uneven wear on the pads and rotors. Always clean new rotors with brake cleaner before installation to ensure optimal performance.

Failing to Check for Brake Fluid Leaks

Brake fluid leaks are a serious issue that can lead to complete brake failure if not addressed promptly. Leaks can occur from damaged brake lines, worn seals in the master cylinder, or faulty calipers. If brake fluid levels drop, it compromises the hydraulic pressure needed for the braking system to function properly. Regularly check for any signs of leaks, such as fluid under the vehicle or a soft brake pedal, and have the system inspected and repaired immediately.

This article originally appeared on MyCarMakesNoise.

More from MyCarMakesNoise

25 Legendary Supercars That Broke Records and Made History

Supercars have always been at the forefront of automotive innovation, pushing the boundaries of speed, design, and technology. In this article, we explore 25 supercars that didn’t just break records—they redefined what’s possible in the automotive world. Read More.

The 20 Best Maritime Museums to Visit Worldwide

Discover the wonders of maritime history with our list of the top 20 must-see maritime museums around the world. These museums offer a fascinating glimpse into the rich heritage of seafaring, shipbuilding, and naval exploration. Read More.

10 Vintage Yachts Still Cruising Seas

Vintage yachts have a timeless allure that captivates both maritime enthusiasts and luxury travelers alike. These vessels, steeped in history and elegance, are more than just boats; they are floating relics of a bygone era that continue to grace the world’s oceans with their presence. Read More.