DIY car repairs can be cost-effective but come with several pitfalls. Without proper tools and expertise, repairs may be incomplete or incorrect, leading to further damage. Safety is a major concern, as working on cars involves handling hazardous materials and heavy components. DIY repairs can also void warranties, and obtaining the right parts can be challenging. Additionally, the time and effort required for repairs can be significant, potentially outweighing the cost savings. Here are some common pitfalls in DIY car repairs.

Contents

Incorrectly Diagnosing the Problem

One of the most common pitfalls in DIY car repairs is incorrectly diagnosing the problem. Without the proper diagnostic tools and experience, DIY mechanics may misidentify the root cause of an issue. This can lead to unnecessary repairs, wasted time, and additional expenses. For example, a car that won’t start could be due to a dead battery, faulty alternator, or bad starter motor. A misdiagnosis could result in replacing the wrong part. Tip: Invest in a quality OBD-II scanner and use reputable online resources or consult with a professional to ensure an accurate diagnosis before proceeding with repairs.

Using the Wrong Tools

Using the wrong tools for a job can damage components and lead to incomplete or unsafe repairs. Specialized automotive tools are designed for specific tasks, such as removing spark plugs, brake calipers, or timing belts. Improvising with the wrong tools can strip bolts, break parts, or cause injuries. Recommendation: Before starting any repair, ensure you have the correct tools for the task. Investing in a good set of automotive tools can save time and prevent damage.

Over-Tightening Bolts

Over-tightening bolts is a common mistake that can strip threads, damage components, and lead to costly repairs. This is especially problematic with aluminum engine parts, which are more susceptible to damage. Using a torque wrench to tighten bolts to the manufacturer’s specifications can prevent this issue. Tip: Always refer to the vehicle’s service manual for the correct torque settings and use a calibrated torque wrench to avoid over-tightening.

Forgetting to Disconnect the Battery

Forgetting to disconnect the battery before starting repairs can lead to electrical shorts, sparks, or even fires. This is especially important when working on electrical components or systems involving fuel. Disconnecting the negative terminal of the battery ensures that the electrical system is safe to work on. Recommendation: Make it a habit to disconnect the battery before starting any major repairs, particularly those involving electrical systems or fuel lines.

Improperly Jacking Up the Car

Improperly jacking up a car can lead to serious injuries and damage to the vehicle. Using the wrong jacking points or failing to use jack stands for support can cause the car to fall. Always use the manufacturer’s recommended jacking points and secure the vehicle with jack stands before working underneath it. Tip: Refer to the vehicle’s manual for the correct jacking points and never rely solely on a hydraulic jack for support.

Not Bleeding the Brakes Correctly

Failing to properly bleed the brakes after a repair can result in air bubbles in the brake lines, leading to a spongy brake pedal and reduced braking performance. This can be dangerous, especially in emergency situations. Recommendation: Use a proper brake bleeding kit and follow the correct sequence for your vehicle’s brake system. Enlist the help of a friend or use a one-man brake bleeding tool to ensure all air is removed from the system.

Using the Wrong Type of Oil

Using the wrong type of oil can affect engine performance and longevity. Different engines require specific oil viscosities and formulations to operate efficiently. Using the incorrect oil can lead to poor lubrication, increased wear, and potential engine damage. Tip: Always refer to the vehicle’s owner manual or the oil filler cap for the recommended oil type and viscosity. When in doubt, consult with a professional.

Failing to Use New Gaskets and Seals

Reusing old gaskets and seals can result in leaks and poor performance. Gaskets and seals are designed to create a tight seal between components, preventing oil, coolant, or air leaks. Using old, worn-out gaskets can compromise the integrity of the repair. Recommendation: Always use new gaskets and seals when reassembling components. This ensures a proper seal and prevents future leaks.

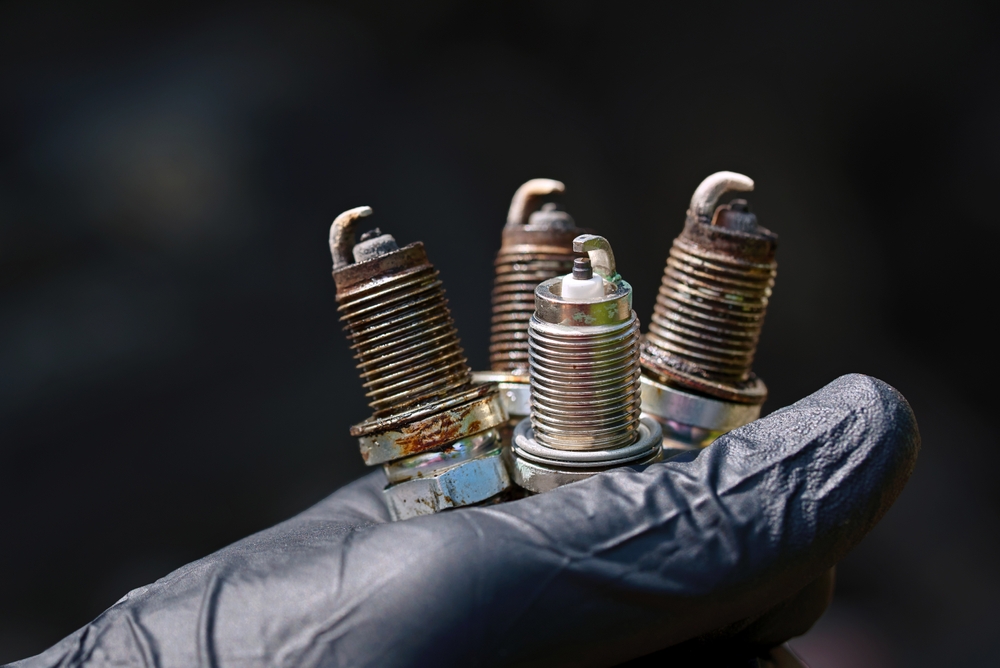

Incorrectly Installing Spark Plugs

Incorrectly installing spark plugs, such as cross-threading or over-tightening them, can damage the cylinder head and affect engine performance. Spark plugs must be installed with the correct torque to ensure proper seating and function. Tip: Use a spark plug socket with a rubber insert to protect the spark plug and a torque wrench to tighten it to the manufacturer’s specifications. Apply a small amount of anti-seize compound on the threads if recommended.

Not Following Proper Torque Specifications

Failing to follow proper torque specifications can lead to under- or over-tightened components, resulting in poor performance, damage, or safety hazards. Each bolt and nut on a vehicle has a specific torque requirement. Using a torque wrench and adhering to the manufacturer’s specifications ensures that components are securely and correctly fastened. Recommendation: Always refer to the vehicle’s service manual for torque specifications and use a calibrated torque wrench to achieve the correct tightness.

Ignoring Safety Precautions

Ignoring safety precautions can result in injuries or accidents. Common safety oversights include not wearing protective gear, working in poorly ventilated areas, and failing to secure the vehicle properly. Safety gear such as gloves, safety glasses, and appropriate clothing can prevent injuries. Recommendation: Prioritize safety by wearing the necessary protective gear, working in a well-ventilated area, and ensuring the vehicle is securely supported before starting any repair.

Improperly Reassembling Components

Improperly reassembling components can lead to malfunctions and further damage. Missing bolts, incorrect alignment, and loose connections are common issues that arise from rushed or careless reassembly. Taking the time to ensure all components are correctly aligned and securely fastened is crucial. Tip: Label and organize parts during disassembly and use the vehicle’s service manual as a reference during reassembly to ensure everything is put back correctly.

Failing to Perform a Test Drive

Failing to perform a test drive after completing repairs can result in unnoticed issues and potential safety hazards. A test drive allows you to check the functionality of the repaired components and ensure everything is working correctly. Recommendation: After completing any repair, take the vehicle for a test drive to confirm that the issue is resolved and that there are no new problems. Pay attention to any unusual noises, vibrations, or performance issues.

Neglecting Regular Maintenance

Neglecting regular maintenance can lead to more significant problems down the line. Skipping routine tasks such as oil changes, filter replacements, and fluid checks can cause engine wear, decreased performance, and costly repairs. Regular maintenance keeps the vehicle in good condition and prevents issues from escalating. Tip: Follow the maintenance schedule outlined in the vehicle’s owner manual and address minor issues promptly to avoid major repairs.

Using Incorrect Parts

Using incorrect or substandard parts can compromise the effectiveness of a repair and lead to further issues. Cheap aftermarket parts may not meet the same quality standards as OEM (original equipment manufacturer) parts. It’s essential to use parts that are specifically designed for your vehicle to ensure compatibility and reliability. Recommendation: When purchasing replacement parts, opt for OEM or high-quality aftermarket parts from reputable suppliers to ensure proper fit and function.

Not Checking Fluid Levels

Failing to check and top off fluid levels after a repair can lead to inadequate lubrication, cooling, or braking performance. Essential fluids such as engine oil, coolant, brake fluid, and transmission fluid must be at the correct levels for optimal operation. Recommendation: After completing any repair, check all fluid levels and top them off as needed. Use the appropriate type of fluid specified in the vehicle’s owner manual.

Overlooking Electrical Connections

Overlooking electrical connections can result in non-functioning components or intermittent issues. Loose, corroded, or improperly connected wires can cause various electrical problems. Ensuring that all electrical connections are secure and free of corrosion is crucial for reliable operation. Tip: Use dielectric grease on electrical connectors to prevent corrosion and ensure a secure connection. Check for any damaged wires and repair or replace them as necessary.

Failing to Calibrate Sensors

Failing to calibrate sensors after certain repairs can lead to inaccurate readings and poor performance. Modern vehicles rely on various sensors to monitor and control engine functions, emissions, and safety systems. After replacing or adjusting components like throttle bodies, MAF sensors, or ABS modules, proper calibration is necessary. Recommendation: Follow the manufacturer’s instructions for sensor calibration and, if needed, use specialized tools or seek professional assistance.

Neglecting Battery Maintenance

Neglecting battery maintenance can lead to starting issues and electrical problems. Corroded terminals, loose connections, and an old battery can cause unreliable performance. Regularly inspecting and maintaining the battery ensures consistent operation. Tip: Clean the battery terminals with a mixture of baking soda and water to remove corrosion, tighten connections, and replace the battery if it shows signs of aging or poor performance.

Not Referring to the Service Manual

Not referring to the vehicle’s service manual can result in incorrect procedures and potential damage. The service manual provides detailed instructions, specifications, and diagrams for repairs and maintenance tasks. Skipping this valuable resource increases the risk of mistakes. Recommendation: Always consult the service manual for your vehicle before starting any repair. It provides essential information that ensures the job is done correctly and safely.

This article originally appeared on MyCarMakesNoise.

More from MyCarMakesNoise

15 Must-Have Items for Flat Tire Emergencies

Getting a flat tire is never convenient, but having the right tools and supplies in your vehicle can turn a potentially stressful situation into a minor delay. From safety gear to practical tools, this guide will walk you through the essential items you should have on hand. Read More.

11 Lightning-Fast Single-Engine Planes You Can Pilot Now

Exploring the skies has never been more exhilarating with the latest advancements in single-engine planes. Combining remarkable speed with cutting-edge technology, these aircraft offer both seasoned pilots and aviation enthusiasts an unparalleled flying experience. Read More.

15 Budget-Friendly Camper Van Mods You Can Afford

Transforming your camper van into a cozy, functional home on wheels doesn’t have to cost a fortune. With a few affordable modifications, you can significantly enhance your comfort and convenience on the road. Read More.