The flywheel is one of the most important components in your car, despite the fact that you may not have the foggiest idea what it is.

That’s about to change.

Here’s a quick breakdown of this ingenious piece of automotive technology and the pivotal role it plays under the hood.

Contents

What Is a Flywheel?

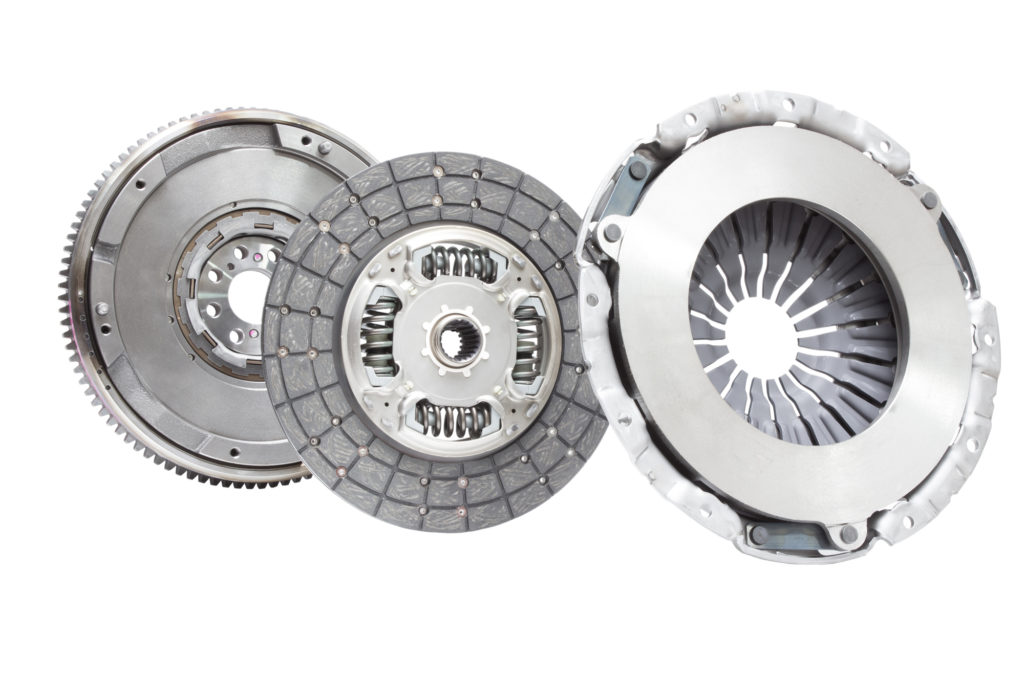

In automotive engineering, a flywheel is a large metal disc designed to store rotational energy generated by the engine and transfer it to the vehicle’s drivetrain system. Its primary job is to ensure that the engine runs smoothly and provides regulated output to other power-dependent parts, such as the drive wheels and the transmission.

Flywheels have been around in one form or another since the early 11th century, and they’re one of the main reasons that cars, trucks, and other automobiles have continued chugging on down the path of progress since they were first introduced to the internal combustion engine a few hundred years ago.

Where Is the Flywheel Located?

The flywheel sits just outside the engine compartment at the rear of the engine, where it’s bookended by the clutch and transmission.

You won’t be able to eyeball your car’s flywheel just by popping the hood—it’s bolted directly to the crankshaft and hidden from view by a protective plate. This plate must be removed in order to provide access to the disc and its neighboring components.

What Is the Purpose of a Flywheel?

Hopefully, you now have a better sense of what an automotive flywheel is and where it’s located. But just what does this gizmo do, exactly? A whole lot, as it turns out.

Why Vehicles Have Flywheels

Flywheels store, deliver, and modulate the vast amounts of rotational energy generated by the dynamic processes that power the internal combustion engine. In other words, they’re responsible for making sure that the engine keeps everything moving the way it’s supposed to.

Consistent power distribution is imperative, as without it, your vehicle would drive in a much choppier manner and you’d have difficulty maintaining a fixed speed on the road.

Working Mechanism

A flywheel is essentially just a big, heavy wheel that turns freely around a rotating shaft.

Without getting too technical, modern car engines have an operating cycle consisting of four distinct piston strokes: the intake stroke, the compression stroke, the ignition stroke, and the power stroke (there’s also an unofficial fifth stroke, the exhaust stroke).

The power stroke is where most of the “oomph” is produced, with the other strokes being relatively subdued. Without a suitable buffer, this peak in power would cause the movement of the drivetrain to speed up and slow down continually.

That’s where the flywheel comes in.

The unique design and considerable heft of this free-spinning disc imbue it with a property known as “moment of inertia.” A flywheel’s moment of inertia enables it to resist changes in rotational speed and revolve at a constant rate, thereby evening out the engine’s intermittent surges.

Pretty neat, huh?

Parts Attached to a Flywheel

The flywheel is bolted directly to the engine crankshaft, with the clutch or torque converter and the rest of the transmission system on the other.

Because of its situation and role in regulating drivetrain function, it’s usually considered part of the transmission, although it has a proverbial hand in many varied aspects of automotive performance.

What if There Were No Flywheels in Vehicles?

Without a flywheel to smooth things out, you would feel a perceptible jerk every time your vehicle’s engine completed the power stroke of its rotational cycle.

Not only that, but your car would eventually die (probably sooner than later), as the flywheel’s other primary duty is to recycle power back into the engine to keep the operating cycle going.

What Does a Flywheel Do in a Manual Transmission?

In manual transmission vehicles, the flywheel serves to direct power both to and from the engine and from the engine to the transmission system. Without it, the driver would be completely unable to travel at a steady speed, change gears, or do much of anything else.

What Does a Flywheel Do in an Automatic Transmission?

Automatic vehicles make use of a variation on the traditional flywheel known as a “flexplate.” The flexplate connects the engine to the torque converter and allows the starter to turn the engine over on startup.

Advantages of a Flywheel in a Car

The flywheel isn’t only there to level out the engine. They also perform or assist in an assortment of other crucial actions. For instance:

It Helps Start the Car

As mentioned, the flexplate variation of the flywheel makes it possible to start automatic transmission vehicles.

It Allows the Car to Run Smoother

Once the engine is active, the flywheel levels out spikes in combustive power to guarantee a seamless and responsive ride.

It Sustains the Engine

The flywheel absorbs the energy produced during the engine’s power stroke and feeds that energy back into the engine during other strokes.

It Powers the Transmission

The flywheel also acts as an intermediary between the engine and the transmission system, taking a portion of the energy harvested from the former and channeling it into the latter.

Flywheel FAQs

Looking to become better acquainted with your vehicle’s flywheel? You’d do well to look over these answers for some of the most-asked questions concerning flywheels and their function.

What Are the Signs of a Bad Flywheel?

Some of the telltale symptoms of a flywheel on the fritz include (but are not limited to):

- Trouble starting your vehicle

- Clutch chatter (intense vibrations in the clutch)

- Inability to change gears

- Frequent gear slippage

- A burning odor

- Unexplained engine shaking or revving

Any of these issues can be a cause for concern on its own, but if you find yourself afflicted by more than one at a time, it’s a good idea to take your vehicle in for a check-up ASAP.

Can You Drive With a Bad Flywheel?

While it’s possible (though certainly not advisable) to roll with a bum flywheel, you’ll no doubt notice a difference in the way your car drives.

Assuming you manage to get it started in the first place, you might feel like the engine or clutch is vibrating to an alarming degree, or you might discover that you can’t shift gears as easily. In the worst-case scenario, you may find that you’re unable to change gears at all.

Even if you’re fortunate enough not to experience any of the above-mentioned defects, you’ll likely feel your engine surging throughout its operating cycle.

What Is the Torque Spec for Flywheel Bolts?

Most manufacturers recommend tightening flywheel and flexplate bolts to a torque setting somewhere between 65 and 75 foot-pounds (the standard unit to measure torque). Some, however, issue substantially higher torque specs. The suggested value generally depends on the exact size of the wheel.

Failure to torque your vehicle’s flywheel to spec could result in damage to the bolt or gradual loosening and displacement of the tensioner.

How Much Does it Cost to Replace a Flywheel?

Having a faulty flywheel replaced is not a one-size-fits-all project in terms of price. This routine job could end up costing you anywhere from $500 to $1,200, depending on a few different factors, most of which will be out of your control.

The bulk of the expense, for example, will be determined by the type of vehicle you drive, the size, weight, and material of the flywheel you need, and whether you opt for an OEM or aftermarket part.

And that’s before you include labor. Making sure your automotive specialist is fairly compensated for their time and efforts could run you an additional $100-500.