A rod knock is one of the first signs of engine trouble. It is a deep knocking sound often caused by damage to the bearings. It can be anything from the bothersome “rattle rattle” or “cancan cancan” sounds, which may intensify depending on the speed and load of the engine.

Contents

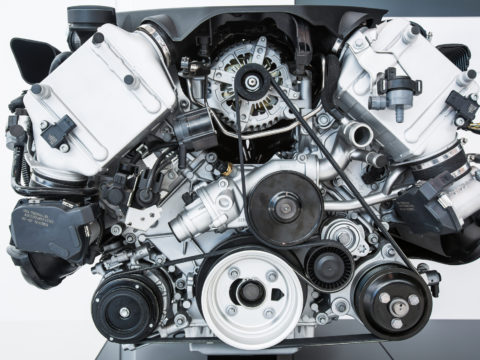

How does a Rod Knock Work?

When the connecting rods within the vehicle’s bearings have more than enough space for clearance, the movement in the engine becomes affected.

As the piston switches direction, the metals hit against each other and produce a loud knocking noise. Also, vehicles with standard engines have pistons moving up and down seamlessly to pump using the combustion power. On the other hand, engines with rod knock experience constant metal-on-metal clash, resulting in the annoying noise coming from the engine.

What Causes a Rod Knock?

The main reason for rod knock trouble is a worn or damaged rod bearing. In addition, it is often the result of the misplaced or missing hydrodynamic oil wedge.

Other possible causes of bearing deterioration include:

- Not enough oil viscosity

- Inadequate flow of oil to the surface of the bearing

- High oil temperature

- Low oil pressure

- Increased level of combustion pressure

- Too much engine revving

- Extreme inertial forces in the piston

How to Diagnose Rod Knock

The annoying sound from the engine can be an obvious sign of rod knock problems. But if you want to be sure, these tips can help you diagnose the rod knock accurately.

Self-diagnosing a Rod Knock

Understanding the sound of the rod knock is crucial to diagnose the problem without taking the vehicle to professional repair service providers. If the low-pitched knocking noise comes from the lower part of the engine with increasing frequency as it picks its speed, it is likely to come from the connecting rods.

But if the knocking sound suddenly disappears once the engine starts to warm up, the engine may be dealing with other problems like a leak in the exhaust gasket. You can always ask for the opinion of a reputable mechanic to have an accurate diagnosis.

If the knocking sound does not go away even after the engine warms up or if you can still hear the annoying sound when the engine while idle, it means that you have to deal with your rod knock problem right away. It may also be the case if you can still hear the same sound if the engine is running with higher revolutions per minute (rpm).

Once you verify that you are dealing with a rod knock, you can fix the problem in your garage if you have all the materials. It includes an adequate supply of fresh oil, an oil filter wrench, oil pans, a brand new oil filter, and a fuel injector cleaner. But it would be best to take the vehicle to the mechanic for professional services.

If the sound subsides after the engine warms up, it could come from a different source. Other engine issues that are commonly mistaken with rod knock include:

- Lifter Tick – The lifter will get destroyed when the camshaft or push rod does not connect continuously with the lifters. It may also cause a loud sound coming from the engine. But unlike rod knocks that have loud and more robust knocking sounds, lifter ticks sound like a tapping or tapping sound.

- Piston Slap – This type of noise comes from combustion engines. It usually goes away once the engine gets warmer.

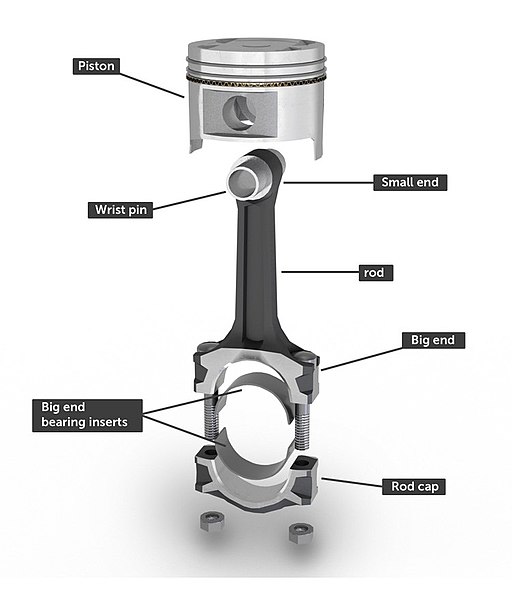

Function of Connecting Rods

Before fixing rod knock problems, it is crucial to understand what connecting rods are and what these parts can do for the engine. This portion of the engine connects the piston with the crankshaft. Therefore, the piston’s linear motion is converted into the crankshaft’s rotary motion. Some of the types of connecting rods include:

- Plain Type Rods – It is used in both inline and opposed engines. The larger end of the connecting rod is connected to the crankpin and fixed with a bearing cap.

- Fork and Blade Rods – Vehicle owners can find these connecting rods on V12 aircraft and V-twin motorcycle engines.

- Master and Slave Rods – Radial engines often use this connecting rod. It is made with a master rod with a direct attachment to the crankshaft.

- Billet Rods – These are higher, stronger, and more durable than most connecting rods since they are made from aluminum or steel. These rods are primarily used in high-speed vehicles.

- Cast Rods – Used by most vehicle manufacturers for engines carrying heavy loads. It is more affordable to produce but not ideal for high horsepower vehicles.

- Forged Rods – This connecting rod is made with either nickel alloy or chrome to boost strength and durability.

- Powered Metal Conrods – It is cheaper than steel rods but stronger than cast rods. It also comes with a finished product mold.

How to Fix Rod Knock

There are several steps to fix the rod knock issues on your engine.

Step 1. Drive the Vehicle to a Set of Mechanic’s Ramps

One of the early fixes for rod knocks is to put fresh oil. You can do it yourself by using a mechanic’s ramp to hoist up. It will allow you to arrange an oil pan under the engine and drain the old oil completely. Next, you must remove the old filter using an oil filter wrench and replace it with a new one. Finally, replace the drained oil with around four to five quarts of new oil once the new filter is already in place.

Step 2: Take Off the Oil Pan to Analyze Your Rod Bearings

The knocking sound on your engine happens when the rod bearing is loose. You may have to tighten the bearing if you find it unfastened or replace it entirely if it does not fit anymore. It is also best to replace the bolts holding the rod bearings if they have the wrong size.

Step 3. Fill the Gas Tank with Fuel-Injection Cleaner

Over time, the grime accumulated at the bottom of your gas tank can make its way into the engine. It can be another reason for rod knocks. It would be best to clean your fuel injection system to avoid the problem.

You also need to prepare at least $2,000 to $4,000 to have this engine issue fixed by a professional mechanic. The computation will depend on the car model and the damage to the engine. It also covers the expenses for the repair labor and parts expenses.

Tips to Prevent Rod Knocks

There are several ways to avoid knocking sounds from your engine, including:

- Filling up gas tanks from trusted gas stations

- Using fuel with higher octane ratings

- Changing spark plugs regularly, depending on the instructions from the manufacturers

- Reducing the engine throttle immediately once you hear a knocking sound

- Removing or preventing carbon deposit accumulation by using high-quality fuel additives created for this purpose

FAQ

What Should I Do if I Hear a Rod Knock?

Rod knock is not a problem that goes away by itself. You must act immediately to fix the problem to avoid causing further damages to the engine.

Can a Rod Knock Go Away?

The only way to get rid of rod knock is to fix it properly. You may do it yourself if you have all the necessary materials. But if you want to avoid the hassles, you can get the services of expert mechanics for more in-depth and accurate solutions.

How Does a Rod Knock Start?

When your rod-bearing gets damaged, the connecting rod will not function properly. It will hinder the engine part’s natural movement. It will result in knocking sounds.

How Long Will an Engine Last with a Rod Knock?

As soon as your engine begins to knock, you may find your rod completely fractured without any warning signs. It could be as fast as your next stop at your driver or as long as six months after the sound appeared. So fix the problem right away to avoid possible trouble in the future.

What Happens if You Ignore a Rod knock?

You will never know when the rod begins to ultimately deteriorate once you hear the loud knocking sound. So if you want to avoid getting stranded in the middle of the road, you need to fix the issue right away.

Can You Replace Rod Bearings Without Machining?

Yes, you can replace them. But you must ensure that there are no nicks on all the surfaces and the replacement parts fit the original size to avoid further problems.