Modern vehicles are more advanced than ever, packed with cutting-edge technology that improves performance, safety, and fuel efficiency. However, while these innovations benefit drivers, they often create headaches for mechanics. Many of the latest vehicle systems are highly complex, requiring specialized tools and extensive training to maintain or repair. What once may have been a straightforward fix can now become a time-consuming and costly ordeal, especially if even a small mistake is made during diagnostics or repairs.

Some technologies are notoriously dreaded in the auto repair industry, from intricate fuel injection systems to sophisticated electric vehicle components. These systems not only demand a high level of expertise but also come with the risk of costly mistakes, making even the most seasoned mechanics wary. In this article, we’ll explore the vehicle technologies that mechanics often dread, highlighting the challenges they present and why they’re so difficult to service.

Contents

Advanced Fuel Injection Systems

Advanced fuel injection systems have transformed engine efficiency but are a headache for many mechanics due to their intricate design. These systems rely on precise sensors and injectors, making troubleshooting difficult without specialized diagnostic equipment. A single faulty sensor can lead to cascading issues, requiring in-depth knowledge to repair correctly. Mechanics also face the risk of damaging expensive components, and mistakes in tuning can result in poor engine performance, making these systems a frequent cause of dread in repair shops.

Complex Electrical Systems

Modern vehicles are packed with sophisticated electrical systems controlling everything from infotainment to safety features. These systems require mechanics to be familiar with advanced diagnostic tools and wiring diagrams, which can be overwhelming without extensive training. Electrical issues often manifest in unpredictable ways, making them hard to pinpoint and fix. The risk of damaging delicate electronic components or triggering faults in other systems increases repair costs and complicates what could be a straightforward job.

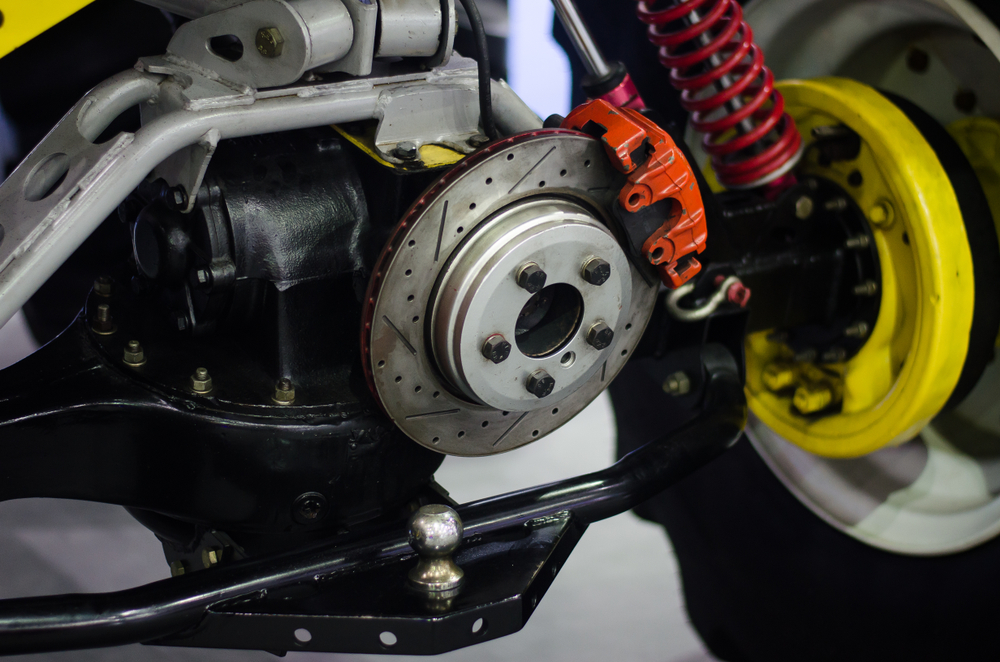

Active Suspension Systems

Active suspension systems are designed to provide a smoother ride by constantly adjusting to driving conditions, but they come with a complexity that few mechanics enjoy tackling. The combination of electronic sensors, hydraulic components, and computer-controlled adjustments creates numerous points of failure. Troubleshooting these systems often requires specialized tools and knowledge, and repairs can be expensive and time-consuming, especially when misdiagnosis leads to unnecessary part replacements.

Dual-Clutch Transmissions

Dual-clutch transmissions offer quick shifts and improved efficiency, but their intricate design makes them difficult to service. Unlike traditional automatic or manual transmissions, dual-clutch systems require a high level of expertise to maintain and repair. These systems are prone to software and mechanical issues, making any mistake during disassembly or reassembly costly. Mechanics need extensive training and specific tools to avoid causing further damage, making this technology one that is often dreaded.

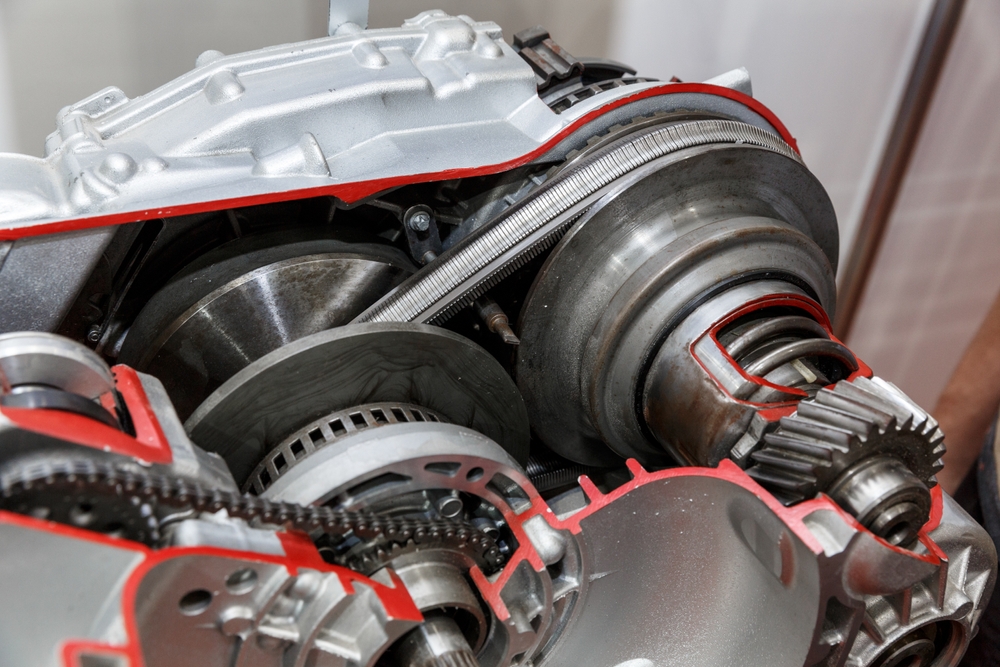

Continuously Variable Transmissions (CVTs)

CVTs are known for their efficiency and smooth acceleration, but they often cause frustration among mechanics due to their unconventional design. Unlike regular transmissions, CVTs use belts and pulleys, which can be difficult to repair and prone to failure. Diagnosing issues is challenging because problems may not manifest in typical ways, and the cost of replacement parts can be steep. Additionally, improper maintenance can lead to catastrophic failure, adding to the reasons why CVTs are dreaded by mechanics.

Start-Stop Systems

Start-stop systems help improve fuel efficiency by shutting off the engine when the vehicle is idle, but they add another layer of complexity for mechanics. These systems rely heavily on battery health, sensors, and electronic control units, making diagnostics more challenging. Frequent start-stop cycles can put additional strain on the engine and starter, leading to more frequent repairs. Mechanics often dread these systems because they are tricky to diagnose, require specialized knowledge, and can be time-consuming to fix.

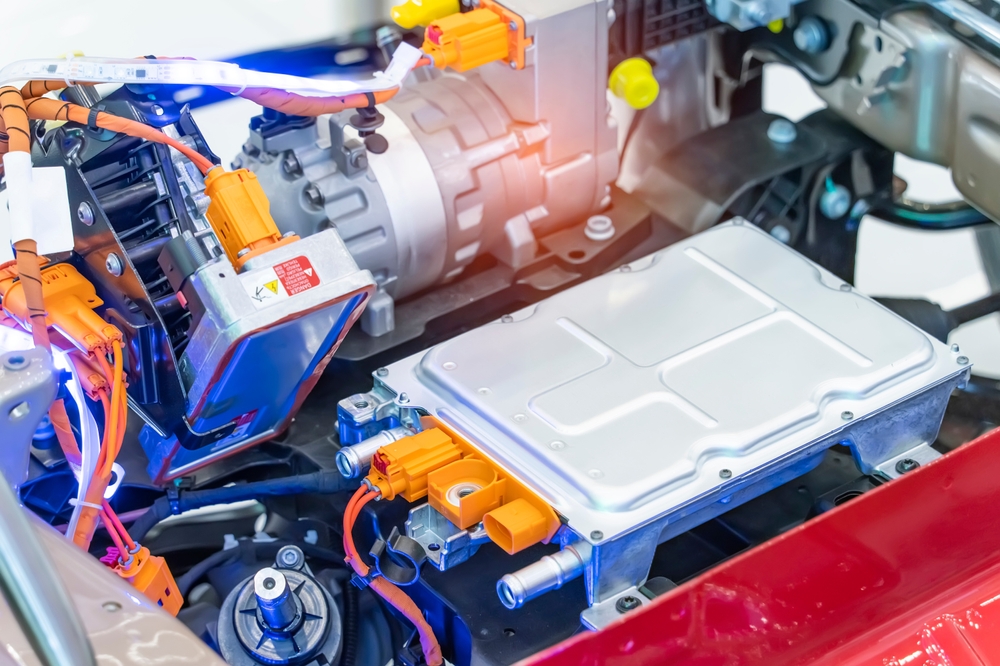

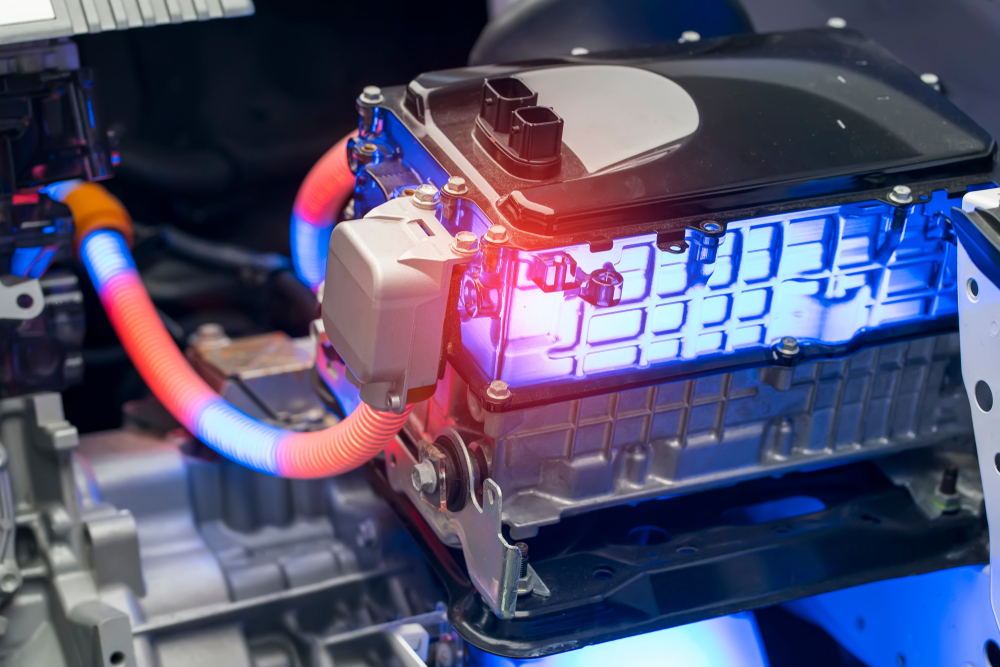

Hybrid and Electric Vehicle Systems

Hybrid and electric vehicle systems represent a leap forward in technology, but they come with steep learning curves for mechanics. The high-voltage batteries, electric motors, and complex powertrain systems demand specialized training and equipment to service safely. Any mistake can lead to dangerous outcomes, including electrical shocks. Mechanics who aren’t equipped to deal with these components often dread working on these vehicles, as missteps can be both costly and hazardous.

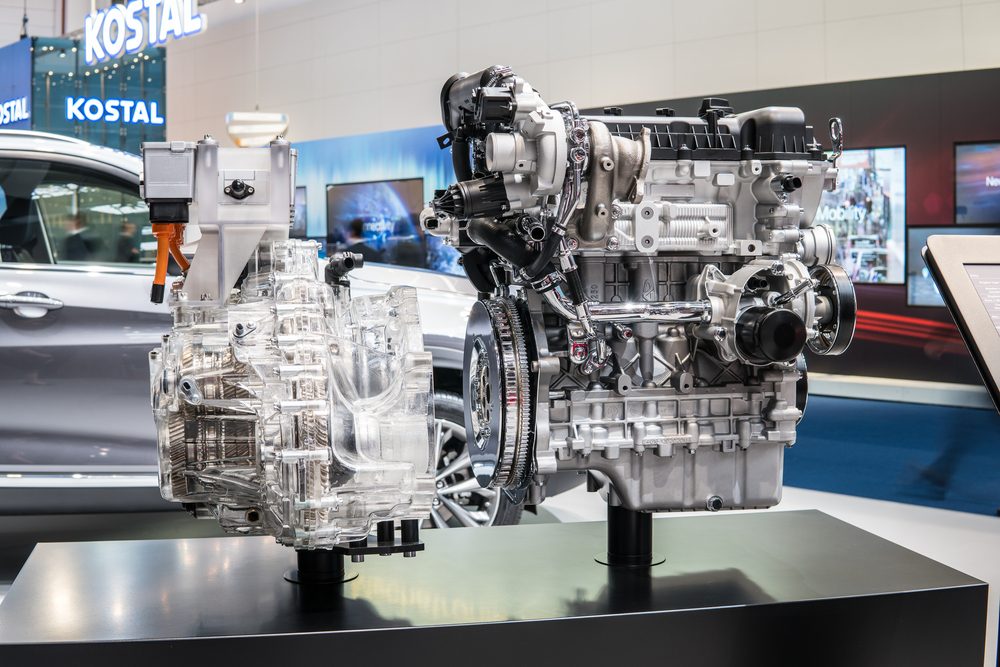

Turbocharged Engines

Turbocharged engines offer impressive performance gains but add another level of difficulty for mechanics. These engines operate under high pressure and temperature, increasing the chances of component failure. Turbochargers are prone to oil leaks, bearing wear, and overheating, requiring precise diagnosis and repair. Mechanics dread working on these systems because even a small error can lead to major engine damage, and replacement parts are often costly.

Lane-Keeping Assist Systems

Lane-keeping assist systems are a welcome safety feature for drivers but a potential nightmare for mechanics. These systems rely on cameras, sensors, and software to detect lane markings and adjust steering. Diagnosing problems can be difficult because issues might arise from any part of the system, from faulty sensors to software glitches. Additionally, recalibrating the system after repairs requires specific tools and expertise, leading to increased frustration and potential for mistakes.

Adaptive Cruise Control

Adaptive cruise control systems, which automatically adjust the vehicle’s speed based on traffic conditions, add another layer of complexity for mechanics. These systems involve radar, sensors, and software that must work seamlessly together. When something goes wrong, pinpointing the source of the problem can be a challenge. Replacing faulty components, especially sensors, can be expensive, and any errors during repair can result in improper system functioning, making mechanics wary of working on these systems.

Keyless Ignition Systems

Keyless ignition systems may seem convenient, but they are another technological advancement that can cause headaches for mechanics. These systems involve wireless communication between the key fob and the vehicle’s computer, which can fail due to battery issues, signal interference, or software malfunctions. Diagnosing and fixing these issues can be tricky, and missteps could disable the vehicle entirely. Mechanics often dread these systems due to their dependence on electronics and the potential for complicated failures.

Variable Valve Timing Systems

Variable valve timing systems optimize engine performance by adjusting valve operation based on driving conditions, but they add significant complexity to engine maintenance. These systems rely on sensors, actuators, and oil pressure to function properly, and even minor malfunctions can lead to poor performance or engine damage. Mechanics often find these systems frustrating because diagnosing issues requires in-depth knowledge, and repairs can be costly if not handled correctly.

This article originally appeared on MyCarMakesNoise.

More from MyCarMakesNoise

13 Least Reliable Cars on the Market

When it comes to choosing a vehicle, reliability is often at the top of the list for most buyers. A car that consistently performs well without frequent visits to the repair shop is what everyone hopes for. Read More.

15 Underrated Luxury Cars That Are Worth Every Penny

In the world of luxury vehicles, certain brands and models often steal the spotlight, leaving other equally impressive options in the shadows. However, for discerning buyers looking to invest in a luxury car that stands out from the crowd, many less-known models offer exceptional value. Read More.

12 Legendary Race Cars Still Competing

In the world of motorsport, certain race cars transcend their time, leaving an indelible mark on the track and in the hearts of racing enthusiasts. These legendary machines, known for their groundbreaking performance and engineering, have not only dominated in their prime but continue to compete, proving their enduring prowess. Read More.