The automotive industry is undergoing a green revolution, with manufacturers embracing innovative methods to create more sustainable vehicles. From electric drivetrains to recycled materials, these game-changing trends are setting new standards for eco-friendly production. In this article, we’ll explore 15 key trends that are transforming vehicle manufacturing, driving the industry toward a cleaner and more sustainable future.

Contents

Electric Vehicles (EVs)

Electric vehicles are transforming the automotive industry by providing a cleaner alternative to traditional gasoline-powered cars. They operate on electric power, eliminating tailpipe emissions and significantly reducing greenhouse gas emissions. Advanced battery technologies, such as lithium-ion batteries, offer longer ranges and faster charging times, making EVs more practical for everyday use. As production scales up, costs are decreasing, further encouraging widespread adoption.

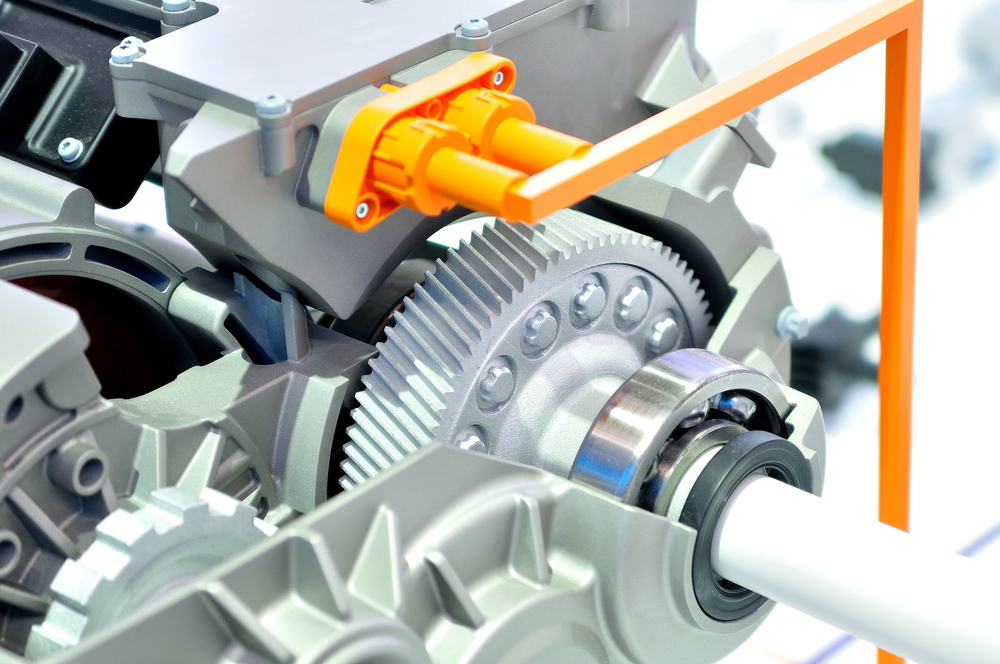

Hybrid Technology

Image Editorial Credit: Shutterstock.com

Hybrid vehicles combine an internal combustion engine with an electric motor, offering improved fuel efficiency and lower emissions compared to conventional cars. This technology allows for regenerative braking, where energy usually lost during braking is captured and reused. Hybrids can switch between or combine power sources to optimize performance and efficiency, making them a versatile option for consumers looking to reduce their environmental impact.

Hydrogen Fuel Cells

Image Editorial Credit: Shutterstock.com

Hydrogen fuel cell vehicles (FCVs) use hydrogen gas to generate electricity, producing only water and heat as byproducts. This zero-emission technology offers a high energy density and rapid refueling times similar to conventional vehicles. Hydrogen FCVs can achieve longer ranges than most battery electric vehicles, making them a promising option for reducing reliance on fossil fuels and cutting greenhouse gas emissions.

Recycled Materials

Image Editorial Credit: Shutterstock.com

Utilizing recycled materials in vehicle production reduces the demand for new raw materials and minimizes waste. Automakers are increasingly incorporating recycled plastics, metals, and even natural fibers into car components. This approach not only conserves resources but also lowers the overall environmental footprint of manufacturing processes, contributing to a circular economy.

Lightweight Construction

Image Editorial Credit: Shutterstock.com

Reducing vehicle weight improves fuel efficiency and reduces emissions. Lightweight materials like aluminum, carbon fiber, and high-strength steel are being used to replace heavier traditional materials. These materials maintain structural integrity and safety while enhancing performance and efficiency, leading to more sustainable vehicle designs.

3D Printing

Image Editorial Credit: Shutterstock.com

3D printing technology allows for precise, on-demand manufacturing of vehicle components, reducing waste and energy consumption. This additive manufacturing process uses only the necessary amount of material, minimizing scrap and enabling complex, lightweight designs. It also accelerates prototyping and production, making the manufacturing process more efficient and environmentally friendly.

Circular Economy Practices

Adopting circular economy principles involves designing vehicles for easy disassembly, repair, and recycling. This approach ensures that materials and components can be reused, refurbished, or recycled at the end of their lifecycle. By closing the loop, manufacturers can reduce waste, conserve resources, and create more sustainable products.

Solar-Powered Vehicles

Integrating solar panels into vehicles can provide a supplementary power source, reducing reliance on external charging or fuel. Solar technology can power auxiliary systems or even contribute to propulsion, enhancing the overall efficiency of electric and hybrid vehicles. This innovation helps lower the environmental impact of driving and offers a renewable energy solution.

Biofuels

Image Editorial Credit: Shutterstock.com

Biofuels are derived from organic materials, such as plants and algae, offering a renewable alternative to fossil fuels. They can be used in existing internal combustion engines with minimal modifications, reducing greenhouse gas emissions and dependence on non-renewable resources. Advanced biofuels, like cellulosic ethanol and biodiesel, provide higher energy outputs and greater environmental benefits.

Sustainable Supply Chains

Ensuring that raw materials and components are sourced ethically and sustainably is crucial for reducing the overall environmental impact of vehicle manufacturing. Sustainable supply chains prioritize the use of renewable resources, minimize waste, and enforce fair labor practices. Transparency and traceability throughout the supply chain help manufacturers meet environmental and social responsibility goals.

Energy-Efficient Manufacturing

Employing energy-saving technologies and processes in manufacturing plants reduces the carbon footprint of vehicle production. Energy-efficient practices include using renewable energy sources, optimizing machinery operation, and implementing smart grid technologies. These measures lower energy consumption, reduce costs, and enhance sustainability in manufacturing.

Vehicle-to-Grid Technology (V2G)

Image Editorial Credit: Shutterstock.com

V2G technology allows electric vehicles to interact with the power grid, feeding stored energy back into the grid during peak demand periods. This bi-directional energy flow helps stabilize the grid, integrate renewable energy sources, and provide backup power during outages. V2G enhances the overall efficiency and sustainability of the energy and transportation sectors.

Advanced Battery Technology

Image Editorial Credit: Shutterstock.com

Developing batteries with longer life spans, higher energy densities, and faster charging times is critical for the widespread adoption of electric vehicles. Innovations such as solid-state batteries, lithium-sulfur batteries, and silicon anodes offer improved performance and safety. These advancements make EVs more practical, efficient, and environmentally friendly.

Eco-Friendly Paints and Coatings

Using non-toxic, water-based paints and coatings reduces the environmental impact of vehicle manufacturing. Traditional paints release volatile organic compounds (VOCs) that contribute to air pollution and health issues. Eco-friendly alternatives minimize VOC emissions, improve worker safety, and enhance the overall sustainability of the production process.

Autonomous Vehicles

Image Editorial Credit: Shutterstock.com

Self-driving cars have the potential to optimize fuel use, reduce emissions, and improve traffic flow. Autonomous vehicles can operate more efficiently than human-driven cars, minimizing unnecessary acceleration and braking. They can also be programmed to choose the most energy-efficient routes, further reducing their environmental impact.

This article originally appeared in MyCarMakesNoise.

More from MyCarMakesNoise

20 Utility Vehicles That Sacrificed Style for Functionality

Utility vehicles are designed for practicality and performance, but not all hit the mark when it comes to style. Some models, despite their functionality, have failed to impress with their design. Read More

20 Car Gadgets That End Up Being More Trouble Than They`re Worth

Car gadgets can promise to enhance your driving experience, but not all of them deliver as expected. Some gadgets can be more trouble than they’re worth, causing frustration and even safety issues. Read More

20 Cars Likely to Be Discontinued in 3 Years

The automotive industry is constantly evolving, with some models being phased out to make way for new innovations. Here are 20 cars that likely won’t exist in three years, due to changing market demands, regulatory pressures, or manufacturer decisions. Read More